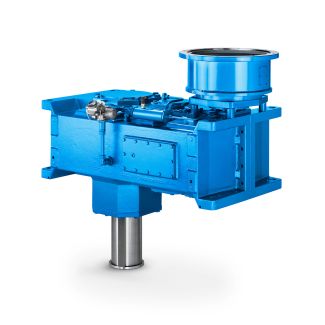

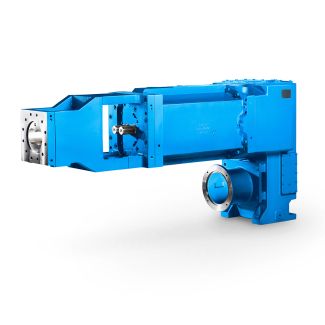

a friedr flender gmbh H3-DH10A Helical speed reducer H3

In stock

SKU

H3-DH10A

$21,857.14

Flender/Flender Gear Units/Helical speed reducer H3

e rotary-cutting ma- chine, with view to developing single-row rotary paddy harvester relative to mechanicaland ergonomic considerations. The schematic diagram of the prototype, with crop guide,is shown in Fig. 7. It was recommended that in such cutters, crop guide assembly

of the prototype, with crop guide,is shown in Fig. 7. It was recommended that in such cutters, crop guide assembly  shouldbe provided with provision to adjust the deector plate angle and blade-shielding platefor effective windrowing. Blade speed, shear angle, blade

shouldbe provided with provision to adjust the deector plate angle and blade-shielding platefor effective windrowing. Blade speed, shear angle, blade  clearance, crop moisture, crop density, and variety showed signicant effect on efcient cutting and windrowing opera- tions. closed-tooth rotary blade

clearance, crop moisture, crop density, and variety showed signicant effect on efcient cutting and windrowing opera- tions. closed-tooth rotary blade  with countercutting edge signicantly reduced shatterloss in the speed range of 3.3.1 /, when compared with blade without counter-cutting edge. However, blade speed beyond 3.1 / reduced shatter loss signicantly.Singh and Verma ( reported that rotary cutter without crop guide assembly would 7 Datta Fig. 7 Prototype of knapsack-type reaper with rotary cutter; observe plant deector and crop divider: 1. Rotary cutter 6. Central crop divider2. Counter-edge plate 7. Auxiliary plant ender 3. Left crop divider 8. Blade-shielding plate 4. Crop guide assembly 9. Safety shield 5. Main plant deector 1. Flexible drive shaft inside exible rubber cover (From Ref. 4.) require three persons for 1.8.0 to harvest 1 ha of cereal crop, and for lodged crops more time would be required, as it is operated against the direction of lodging and operatedidle while traveling in the direction of lodging (. Figure 8 shows the sectional view of Japanese model ( lightweight, portable, 1.0- Mametora reaper (Model: SM that uses mainly single planetary rotary sawas blade, dividing rods, guide rod, straw-gathering, and disposing levers for paddy crops. This unit is for mounting at the front of 3.5 hp two-wheel gasoline tractor (power tiller, model Mametora UK. The reaper input shaft receives the drive from the tractor pulley through -belt and pulley. Before the reaping operation, it required manual harvestingto clea

with countercutting edge signicantly reduced shatterloss in the speed range of 3.3.1 /, when compared with blade without counter-cutting edge. However, blade speed beyond 3.1 / reduced shatter loss signicantly.Singh and Verma ( reported that rotary cutter without crop guide assembly would 7 Datta Fig. 7 Prototype of knapsack-type reaper with rotary cutter; observe plant deector and crop divider: 1. Rotary cutter 6. Central crop divider2. Counter-edge plate 7. Auxiliary plant ender 3. Left crop divider 8. Blade-shielding plate 4. Crop guide assembly 9. Safety shield 5. Main plant deector 1. Flexible drive shaft inside exible rubber cover (From Ref. 4.) require three persons for 1.8.0 to harvest 1 ha of cereal crop, and for lodged crops more time would be required, as it is operated against the direction of lodging and operatedidle while traveling in the direction of lodging (. Figure 8 shows the sectional view of Japanese model ( lightweight, portable, 1.0- Mametora reaper (Model: SM that uses mainly single planetary rotary sawas blade, dividing rods, guide rod, straw-gathering, and disposing levers for paddy crops. This unit is for mounting at the front of 3.5 hp two-wheel gasoline tractor (power tiller, model Mametora UK. The reaper input shaft receives the drive from the tractor pulley through -belt and pulley. Before the reaping operation, it required manual harvestingto clea| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1020.000000 |

| Ratio Range | 1 : 31.5…112 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 44200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Industriegetriebe GmbH |

| Country of Manufacture | China |

| Data Sheet & Drawings | a friedr flender gmbh H3-DH10A Helical speed reducer H3 |