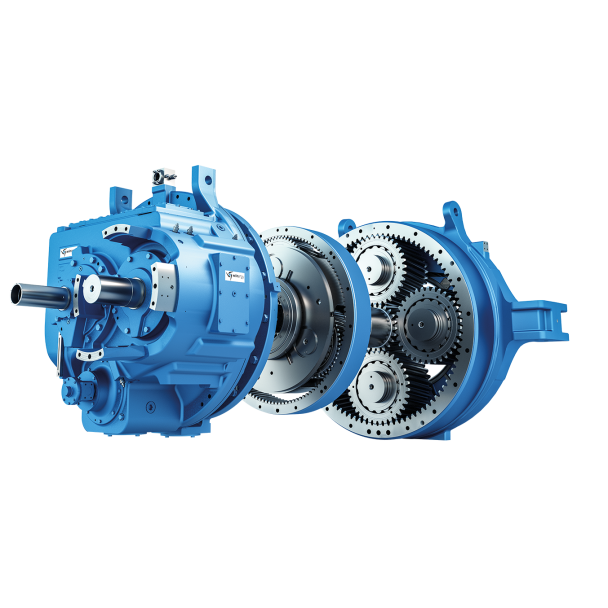

H2-SH17-B flender brasil redutores Helical gearbox H2

In stock

SKU

H2-SH17-B

$99,642.86

Flender/Flender Gear Units/Helical gearbox H2

/ 2 F1 / 2 F1 / 2 F1 / 2 F1 / 2 F1 / 2 F1 / 2 Density, based on DIN at 1 approx. 8 kg/ approx. 8 kg/ approx. 8 kg/ approx. 8 kg/ approx. 8

Density, based on DIN at 1 approx. 8 kg/ approx. 8 kg/ approx. 8 kg/ approx. 8 kg/ approx. 8  kg/ approx. 9 kg/ approx. 9 kg/ approx. 9 kg/ approx. 9 kg/ Kinematic viscosity, DIN 5 pt. 0/ASTM -4/ASTM

kg/ approx. 9 kg/ approx. 9 kg/ approx. 9 kg/ approx. 9 kg/ Kinematic viscosity, DIN 5 pt. 0/ASTM -4/ASTM  7, 4 Capprox. 4 mm/ approx. 6 mm/ approx. 1 mm/ approx. 1 mm/ approx. 2 mm/ approx. 3 mm/

7, 4 Capprox. 4 mm/ approx. 6 mm/ approx. 1 mm/ approx. 1 mm/ approx. 2 mm/ approx. 3 mm/  approx. 4 mm/ approx. 6 mm/ approx. 1 0 mm/ Kinematic viscosity, DIN 5 pt. 0/ASTM -4/ASTM 7, 1 Capprox. 7 mm/ approx. 9 mm/ approx. 1 mm/ approx. 1 mm/ approx. 1 mm/ approx. 2 mm/ approx. 3 mm/ approx. 3 mm/ approx. 4 mm/ Viscosity index, DIN ISO 2 >= 9 >= 9 >= 9 >= 9 >= 9 >= 9 >= 9 >= 8 >= 8 ISO viscosity grade, DIN ISO 3 4 6 1 1 2 3 4 6 1 0 Flash point, DIN EN ISO 2, Cleveland, open -cup apparatus >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 Pour point, DIN ISO 3 <= -2 <= -1 <= -1 <= -1 <= -1 <= -1 <= -1 <= -5 <= -3 Foam test, ASTM - 8, ISO 6, sequence /2 <= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml Foam test, ASTM - 8, ISO 6, sequence II/ 9.5 <= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml Foam test, ASTM 8, ISO 6, sequence III/2C <= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml Ageing properties, ASTM 2, increase in viscosity <= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 % FZG scuffing test, DIN ISO 1-1, /8.3/9, scuffing load stage >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 FZG scuffing test, based on DIN ISO 1-1, /1.6/9, scuffing load stage >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 API scuffing load capacity API GL 4 API GL 4 API GL 4 API GL 4 API GL 4 API GL 4 FAG FE8 rolling bearing test, DIN 5-3, 7,5/8-8, wear of rolling element <= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 2 mg FAG FE8 rolling bearing test, DIN 5-3, 7,5/8-8, wear of cage <= 2 mg<= 2 mg<= 2 mg<= 2 m

approx. 4 mm/ approx. 6 mm/ approx. 1 0 mm/ Kinematic viscosity, DIN 5 pt. 0/ASTM -4/ASTM 7, 1 Capprox. 7 mm/ approx. 9 mm/ approx. 1 mm/ approx. 1 mm/ approx. 1 mm/ approx. 2 mm/ approx. 3 mm/ approx. 3 mm/ approx. 4 mm/ Viscosity index, DIN ISO 2 >= 9 >= 9 >= 9 >= 9 >= 9 >= 9 >= 9 >= 8 >= 8 ISO viscosity grade, DIN ISO 3 4 6 1 1 2 3 4 6 1 0 Flash point, DIN EN ISO 2, Cleveland, open -cup apparatus >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 >= 2 Pour point, DIN ISO 3 <= -2 <= -1 <= -1 <= -1 <= -1 <= -1 <= -1 <= -5 <= -3 Foam test, ASTM - 8, ISO 6, sequence /2 <= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml Foam test, ASTM - 8, ISO 6, sequence II/ 9.5 <= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml Foam test, ASTM 8, ISO 6, sequence III/2C <= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml<= 1/1 ml Ageing properties, ASTM 2, increase in viscosity <= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 %<= 6 % FZG scuffing test, DIN ISO 1-1, /8.3/9, scuffing load stage >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 FZG scuffing test, based on DIN ISO 1-1, /1.6/9, scuffing load stage >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 >= 1 API scuffing load capacity API GL 4 API GL 4 API GL 4 API GL 4 API GL 4 API GL 4 FAG FE8 rolling bearing test, DIN 5-3, 7,5/8-8, wear of rolling element <= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 3 mg<= 2 mg FAG FE8 rolling bearing test, DIN 5-3, 7,5/8-8, wear of cage <= 2 mg<= 2 mg<= 2 mg<= 2 m| Model Type | Helical gearbox H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 4650.000000 |

| Ratio Range | 1 : 6.3…20 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 195000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER GRAFFENSTADEN |

| Country of Manufacture | Iceland |

| Data Sheet & Drawings | H2-SH17-B flender brasil redutores Helical gearbox H2 |