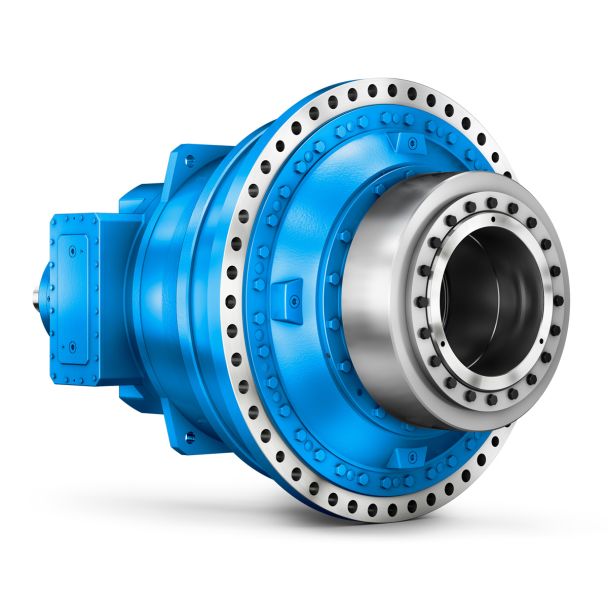

H2-SH-18B n eupex coupling catalogue Helical speed reduction gearbox H2

In stock

SKU

H2-SH-18B

$109,821.43

Flender/Flender Gear Units/Helical speed reduction gearbox H2

/ specifications referred to in the relevant code of fabrication shall be followed for the welding/ brazing qualifications, consumable qualifications and non des tructive test procedures. ) Standard for welding of pipelines and related facilities PI-1. ii) Material Specifications -

and non des tructive test procedures. ) Standard for welding of pipelines and related facilities PI-1. ii) Material Specifications -  Welding rods, electrodes and filler materials - ASME Sec. - IIC. iii) Code for non destructive examination ASME Sec-. iv)

Welding rods, electrodes and filler materials - ASME Sec. - IIC. iii) Code for non destructive examination ASME Sec-. iv)  Qualification standard for welding and brazing procedure and welders, brazers, welding and brazing operators - ASME Sec- 1 of 1

Qualification standard for welding and brazing procedure and welders, brazers, welding and brazing operators - ASME Sec- 1 of 1  STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 1 of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 In the event of any difference due to the additional requirem ents mentioned in this specification, over and above those obligation as per codes, this specification shall be binding. 1.2 Base Material ) In general carbon steel is used in this plant. The details of material specifications are given in the welding Specification Chart. ) The contractor shall provide the Manufacturer' test certificates for every heat of the materials supplied by him. 1.3A Filler Materials ) The Contractor shall provide all the necessary welding ele ctrodes, filler materials, etc. required for the execution of the work. ) The welding electrodes/ filler wires supplied by the Contractor shall conform to the class specified in the welding specification chart. The materials shall be of the make approved by the Engineer-in-charge. ) The electrode shall be suitable for the welding process recommended and base metal used. Unless otherwise specified physical properties of the welds produced by electrode recommended for the welding of partic ular base metal shall not be lower than the minimum valves specified for the base metal and shall correspond to the physical properties of the class of electrode adopted. The choice of electrode sha

STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 1 of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 In the event of any difference due to the additional requirem ents mentioned in this specification, over and above those obligation as per codes, this specification shall be binding. 1.2 Base Material ) In general carbon steel is used in this plant. The details of material specifications are given in the welding Specification Chart. ) The contractor shall provide the Manufacturer' test certificates for every heat of the materials supplied by him. 1.3A Filler Materials ) The Contractor shall provide all the necessary welding ele ctrodes, filler materials, etc. required for the execution of the work. ) The welding electrodes/ filler wires supplied by the Contractor shall conform to the class specified in the welding specification chart. The materials shall be of the make approved by the Engineer-in-charge. ) The electrode shall be suitable for the welding process recommended and base metal used. Unless otherwise specified physical properties of the welds produced by electrode recommended for the welding of partic ular base metal shall not be lower than the minimum valves specified for the base metal and shall correspond to the physical properties of the class of electrode adopted. The choice of electrode sha| Model Type | Helical speed reduction gearbox H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 5125.000000 |

| Ratio Range | 1 : 7.1…22.4 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 230000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | Ireland |

| Data Sheet & Drawings | H2-SH-18B n eupex coupling catalogue Helical speed reduction gearbox H2 |