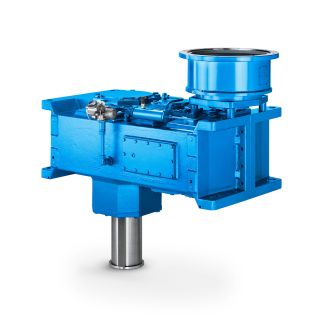

Bevel-helical gearbox B3 lubrication approximately h can be assumed as re B3-VV9-B

In stock

SKU

B3-VV9-B

$19,285.71

Flender/Flender Gear Units/Bevel-helical gearbox B3

or in this application Option for compressed air feed to main gear case, providing positive pressure to further reduce risk of dust ingress Designed to handle overload conditions Each gearbox is designed to ensure inspection and maintenance points are easily

of dust ingress Designed to handle overload conditions Each gearbox is designed to ensure inspection and maintenance points are easily  accessible Further VMX unit siz es available on equest. THRUST LOAD MOTOR INPUT OUTPUT (TYPICAL) POWER SPEED SPEED WEIGHT kN

accessible Further VMX unit siz es available on equest. THRUST LOAD MOTOR INPUT OUTPUT (TYPICAL) POWER SPEED SPEED WEIGHT kN  HP RPM RPM lbs VMX4 1 6 9 4 1 VMX5 1 6 9 3 1 VMX5 1 7 9

HP RPM RPM lbs VMX4 1 6 9 4 1 VMX5 1 6 9 3 1 VMX5 1 7 9  3 2 VMX6 2 8 9 3 3 VMX6 2 9 9 3 3 VMX7 2 9 9 3 4 VMX8 3 1 9 2 5 VMX9 5 1 9 2 7 VMX1 5 1 9 2 8David Br own gearbo modelProduct range includes: Power station Power station Power station Power station Power station Power stationPower station Power station Power stationPower stationPower stationPower stationChina China India China China CanadaCanada China Canada ChinaChina Hong Kong6 1Country Name of customer Motor power (kW) QuantityReference list includes: Various Power Station equipped with LOESCHE classifiers - Ratcliff, UK LOESCHE mill type LM2 - Schwarze Pumpe, Germany LOESCHE mill type LM2 - Avedore, Denmark Key features Double helical gearing is supplied as standard but single helical gears can be incorporated to suit customer requirements All HX gearboxes are designed to limit sound pressure levels to meet your noise emissions standards All high speed gearboxes are no-load tested at full operating speed. Load testing and back-to-back testing programmes are available if required Oil reservoirs and housings that enclose moving lubricated parts are designed to minimise contamination by moisture, dust and other foreign matter during operation and when staticGearbox design features The HX range is designed and manufactured to all major international standards including: API6, API6, AGMA6, AGMA4.0, ISO and DIN Flexible gear case configuration allows for the positioning of oil inlets either side, or at the

3 2 VMX6 2 8 9 3 3 VMX6 2 9 9 3 3 VMX7 2 9 9 3 4 VMX8 3 1 9 2 5 VMX9 5 1 9 2 7 VMX1 5 1 9 2 8David Br own gearbo modelProduct range includes: Power station Power station Power station Power station Power station Power stationPower station Power station Power stationPower stationPower stationPower stationChina China India China China CanadaCanada China Canada ChinaChina Hong Kong6 1Country Name of customer Motor power (kW) QuantityReference list includes: Various Power Station equipped with LOESCHE classifiers - Ratcliff, UK LOESCHE mill type LM2 - Schwarze Pumpe, Germany LOESCHE mill type LM2 - Avedore, Denmark Key features Double helical gearing is supplied as standard but single helical gears can be incorporated to suit customer requirements All HX gearboxes are designed to limit sound pressure levels to meet your noise emissions standards All high speed gearboxes are no-load tested at full operating speed. Load testing and back-to-back testing programmes are available if required Oil reservoirs and housings that enclose moving lubricated parts are designed to minimise contamination by moisture, dust and other foreign matter during operation and when staticGearbox design features The HX range is designed and manufactured to all major international standards including: API6, API6, AGMA6, AGMA4.0, ISO and DIN Flexible gear case configuration allows for the positioning of oil inlets either side, or at the| Model Type | Bevel-helical gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 900.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER GRAFFENSTADEN |

| Country of Manufacture | China |

| Data Sheet & Drawings | Bevel-helical gearbox B3 lubrication approximately h can be assumed as re B3-VV9-B |