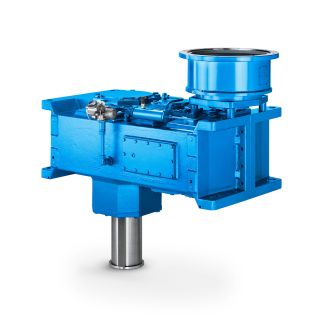

Bevel-helical gear box B3 quired space for piping and monitoring details ac B3VV-9-C

In stock

SKU

B3VV-9-C

$19,285.71

Flender/Flender Gear Units/Bevel-helical gear box B3

or inc?ustrial weaving The finishin processes, which fofows the weaving operation, are strongly impaired by the sizing agent \ fabric is therefore "desized" prior to finishing, which means, that the sizing agent is washed-off from the fabric In the case

is therefore "desized" prior to finishing, which means, that the sizing agent is washed-off from the fabric In the case  of starch based sizing agents, which are widely used in Egypt and which are not water soluble, the starch has

of starch based sizing agents, which are widely used in Egypt and which are not water soluble, the starch has  to be broken down by enzymes into water soluble form prior to washing With this process,all properties which are relevant

to be broken down by enzymes into water soluble form prior to washing With this process,all properties which are relevant  for sizing, get lost The degredated starch has novalueand is therefore discharged into the effluent Sofar,the effluents have been directed unfortunately without any clearing into the River Nile, which is the only source for potable water For this reason it was of great interest to the Eg ptian side to develop practic- able techniques for reduction or elimination of the dischargeJsizing agent 2, Working steps The proposal of NRC, which formed the base of the project, aimed to develop water soluble starch based sizing agents, which do not require degredation rocess before washing The ultrafiltration (UF) The generated concentrate should then be reused as sizing agent What formerly polluted the drinking water is thereby transformed into valuable product In orderto achieve the proposed target, basic research and develop work had be done in order to develop reclaimableand reusablewatersolublestarchsizesaswell astoachieve practicable techniques for reclamation 3. Results The developed products were tested in an Egyptian mill The Gesellschaft fur Trennverfahren mbH (GTV) Bodelshausen, Germany, developed pilot ultrafiltration unit which was set in "Misr Spinnin and Weaving Company", Mahalla The production of the water solublestarcRes was done at % "Egyptian Starch and Glucose Manufacturing Company", Cairo Within large scale tests the developed starches were tested successfully throughout the whole line of sizing, weavin3, desizing and ultrafiltration The concentrate,

for sizing, get lost The degredated starch has novalueand is therefore discharged into the effluent Sofar,the effluents have been directed unfortunately without any clearing into the River Nile, which is the only source for potable water For this reason it was of great interest to the Eg ptian side to develop practic- able techniques for reduction or elimination of the dischargeJsizing agent 2, Working steps The proposal of NRC, which formed the base of the project, aimed to develop water soluble starch based sizing agents, which do not require degredation rocess before washing The ultrafiltration (UF) The generated concentrate should then be reused as sizing agent What formerly polluted the drinking water is thereby transformed into valuable product In orderto achieve the proposed target, basic research and develop work had be done in order to develop reclaimableand reusablewatersolublestarchsizesaswell astoachieve practicable techniques for reclamation 3. Results The developed products were tested in an Egyptian mill The Gesellschaft fur Trennverfahren mbH (GTV) Bodelshausen, Germany, developed pilot ultrafiltration unit which was set in "Misr Spinnin and Weaving Company", Mahalla The production of the water solublestarcRes was done at % "Egyptian Starch and Glucose Manufacturing Company", Cairo Within large scale tests the developed starches were tested successfully throughout the whole line of sizing, weavin3, desizing and ultrafiltration The concentrate,| Model Type | Bevel-helical gear box B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 900.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Ges.m.b.H. |

| Country of Manufacture | New Zealand |

| Data Sheet & Drawings | Bevel-helical gear box B3 quired space for piping and monitoring details ac B3VV-9-C |