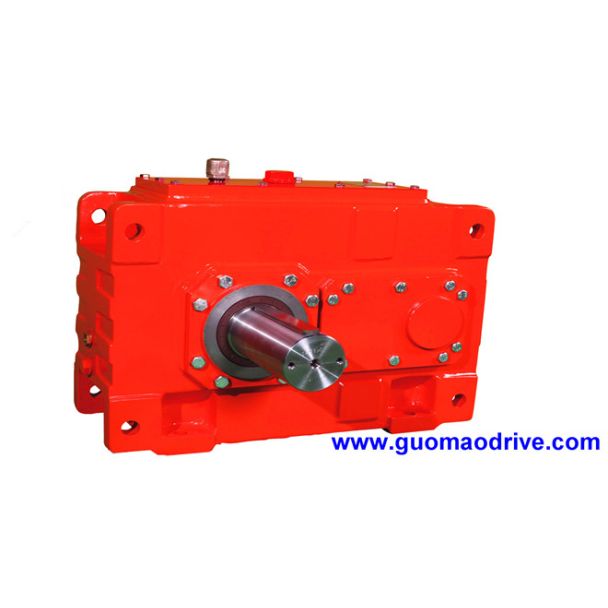

Bevel-helical gear reducer B3 cording to orderrelated documentation Free spac B3-VV-9-D

In stock

SKU

B3-VV-9-D

$19,285.71

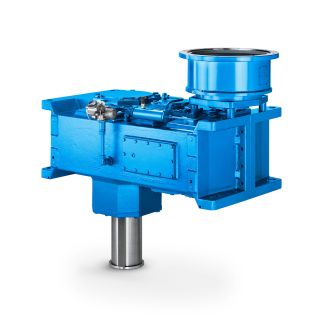

Flender/Flender Gear Units/Bevel-helical gear reducer B3

or it also enables an equipment monitoring to shorten downtimes and optimize plant availability. FLENDER REMOTE EXPERT Digital option to continue servicing your gear unit while off site. We enable your own service personnel on site to accomplish the required

continue servicing your gear unit while off site. We enable your own service personnel on site to accomplish the required  scope of service by providing Flender support via HD video transmission, document sharing and annotation features.YOUR BENEFITS AT GLANCE OUR

scope of service by providing Flender support via HD video transmission, document sharing and annotation features.YOUR BENEFITS AT GLANCE OUR  FLENDER SERVICES flender HB series gearbox ----------------------------------------------------------------- Flender GmbH Alfred-Flender-Strae 7 4 Bocholt Germany Article No.: FLEX-B1-0-7 Printed in Germany

FLENDER SERVICES flender HB series gearbox ----------------------------------------------------------------- Flender GmbH Alfred-Flender-Strae 7 4 Bocholt Germany Article No.: FLEX-B1-0-7 Printed in Germany  Dispo 2 BR 1.0 The information provided in this catalog contains descriptions or charac- teristics of performance which in case of actual use do not always apply as described or which may change as result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract. Availability and technical specifications are subject to change without notice. All product designations may be trademarks or product names of Flender or supplier companies whose use by third parties for their own purposes could violate the rights of the owners. ----------------------------------------------------------------- 2h Service Emergency Hotline: +4 (0) 1 - 2 1 1 ----------------------------------------------------------------- Analysis of justification for applying two gear sets within the universal gear reducers Milan Rackov1,*, Sinia Kuzmanovi1, Ivan Kneevi1, Maja avi1, and Marko Peni1 1University of Novi Sad, Faculty of Technical Sciences, 6 Tr Dositeja Obradovia, 2 Novi Sad, Serbia Abstract. In the area of universal gear reducers, standard does not prescribe relations between load capacity, gear ratios and axis heights. Therefore, larger load capacity of some gear reducers manufacturers has advantage for lower gear ratio and, vice versa, smaller load capacity of the gearbox achi

Dispo 2 BR 1.0 The information provided in this catalog contains descriptions or charac- teristics of performance which in case of actual use do not always apply as described or which may change as result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract. Availability and technical specifications are subject to change without notice. All product designations may be trademarks or product names of Flender or supplier companies whose use by third parties for their own purposes could violate the rights of the owners. ----------------------------------------------------------------- 2h Service Emergency Hotline: +4 (0) 1 - 2 1 1 ----------------------------------------------------------------- Analysis of justification for applying two gear sets within the universal gear reducers Milan Rackov1,*, Sinia Kuzmanovi1, Ivan Kneevi1, Maja avi1, and Marko Peni1 1University of Novi Sad, Faculty of Technical Sciences, 6 Tr Dositeja Obradovia, 2 Novi Sad, Serbia Abstract. In the area of universal gear reducers, standard does not prescribe relations between load capacity, gear ratios and axis heights. Therefore, larger load capacity of some gear reducers manufacturers has advantage for lower gear ratio and, vice versa, smaller load capacity of the gearbox achi| Model Type | Bevel-helical gear reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 900.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | Nicaragua |

| Data Sheet & Drawings | Bevel-helical gear reducer B3 cording to orderrelated documentation Free spac B3-VV-9-D |