H4VH-15-C le added value Drive systems from Flender ensur Helical gear unit H4

In stock

SKU

H4VH-15-C

$49,178.57

Flender/Flender Gear Units/Helical gear unit H4

fragments and particularly free of any discoloring specks. Figure 9 shows cleaning house diagram of corn. After the corn is weighed in scale it passes through magnet for removal of tramp metal. It then passes on to grainseparator with an

weighed in scale it passes through magnet for removal of tramp metal. It then passes on to grainseparator with an  aspiration channel. This removes impurities that are larger, ner, andlighter than corn. This machine is also equipped with an air-recycling

aspiration channel. This removes impurities that are larger, ner, andlighter than corn. This machine is also equipped with an air-recycling  system that allowsefcient aspiration of lighter foreign materials without requiring the energy as would be conventionally perceived. After the bulk

system that allowsefcient aspiration of lighter foreign materials without requiring the energy as would be conventionally perceived. After the bulk  of the foreign material is removed it moves on to destoner for removal of stones the sizes of which are similar to that of corn. Generally, this is the extent of cleaning that is required. The cleaned corn passes on to tempering system where, depending on the degermination and the milling processapplied, the addition of moisture and tempering time are determined. This particular clean-ing diagram also shows conditioning unit that provides moisture addition at high temper- atures to help loosen the bran and germ before it is dehulled and degerminated in the next machine in sequence. This equipment is shown in Fig. 1 and described in detail later. 2.2.1.2 Tempering or Conditioning The type of end products, quality, and the extraction level requirements would determine the level of degermination and the appropriate milling process necessary to accomplish Specialty Milling 3 Fig. 9 Corn cleaning and degerming operation. (Courtesy of Bu hler, Inc.) Fig. 1 Conditioning unit for corn. (Courtesy of Bu hler, Inc.) 3 Sarkar the objectives. Once the level of degermination and the milling requirements have been identied, the tempering requirements can then be determined. As in wheat our milling,the optimum milling moisture and tempering time are targeted for removal of bran. Incorn milling, these parameters focus on both the removal of the bran and germ. Becausecomplete removal of germ may be considered critical to varying degree, depending on the combin

of the foreign material is removed it moves on to destoner for removal of stones the sizes of which are similar to that of corn. Generally, this is the extent of cleaning that is required. The cleaned corn passes on to tempering system where, depending on the degermination and the milling processapplied, the addition of moisture and tempering time are determined. This particular clean-ing diagram also shows conditioning unit that provides moisture addition at high temper- atures to help loosen the bran and germ before it is dehulled and degerminated in the next machine in sequence. This equipment is shown in Fig. 1 and described in detail later. 2.2.1.2 Tempering or Conditioning The type of end products, quality, and the extraction level requirements would determine the level of degermination and the appropriate milling process necessary to accomplish Specialty Milling 3 Fig. 9 Corn cleaning and degerming operation. (Courtesy of Bu hler, Inc.) Fig. 1 Conditioning unit for corn. (Courtesy of Bu hler, Inc.) 3 Sarkar the objectives. Once the level of degermination and the milling requirements have been identied, the tempering requirements can then be determined. As in wheat our milling,the optimum milling moisture and tempering time are targeted for removal of bran. Incorn milling, these parameters focus on both the removal of the bran and germ. Becausecomplete removal of germ may be considered critical to varying degree, depending on the combin| Model Type | Helical gear unit H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Brasil Ltda |

| Country of Manufacture | Fiji |

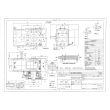

| Data Sheet & Drawings | H4VH-15-C le added value Drive systems from Flender ensur Helical gear unit H4 |