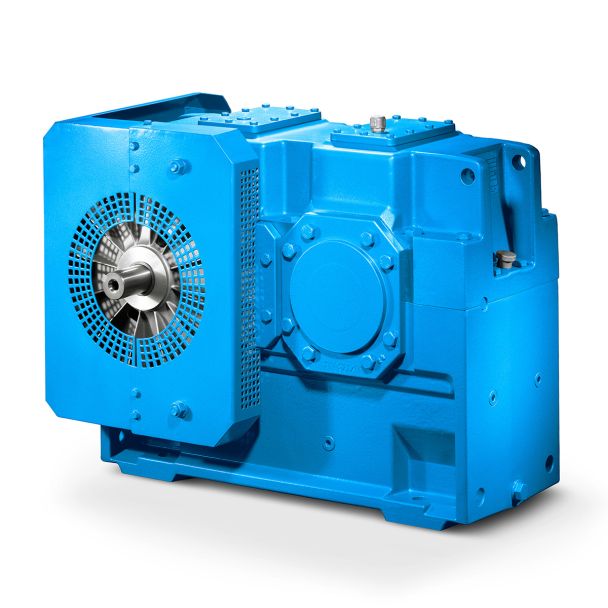

H4-VH-15-D e maximum productivity energy efficiency and Helical gearbox H4

In stock

SKU

H4-VH-15-D

$49,178.57

Flender/Flender Gear Units/Helical gearbox H4

francs, or only 8 percent Major foreign markets include the EC and Scandinavian countries. Research and development & is done mainly on cooperative basis, although gear production benefits from proprietary research conducted by large multinational firms in their home countries.

mainly on cooperative basis, although gear production benefits from proprietary research conducted by large multinational firms in their home countries.  Topics include different manufacturing technologies, such as machining, foundry, and robotics. This cooperative research is funded on 5/5 basis by

Topics include different manufacturing technologies, such as machining, foundry, and robotics. This cooperative research is funded on 5/5 basis by  the industry association, Fabrimetal, and the Belgian Govenunent 8 Employment and training The Belgian gear industry employs approximately 5,5 people,

the industry association, Fabrimetal, and the Belgian Govenunent 8 Employment and training The Belgian gear industry employs approximately 5,5 people,  most of whom are in the automotive sector. Hourly compensation costs for production workers in industrial and commercial machinery manufacturing (SIC rose 1 percent during 1-8, from 5.5 Belgian francs in 1 to 5.3 Belgian francs in 1. In dollars, hourly compensation costs grew nearly 7 percent, from $9.0 in 1 to $1.7 in 1. 8 Most workers in the gear industry are unionized. According to industry officials, the union restricts employers' flexibility in the areas of layoffs and the number of hours worked. (") USITC staff interviews with gear industry officials, BelgiusaNtaofvoermber 1 1not Yet available. Unpublished data from the .. Bureau of Labor Statistics, August 1. Table 8-1 Leading Belgian gear producers, by major sectors, 1 Company Vehicle Industrial Marine Aerospace ABT Asco Clark Components CMI Transmissions David Brown Sad Defawes Esco Transmissions Ford Tractor Hansen Transmissions int' Twin Disc Volvo Cars Watteeuw Source: Fabrimetal. 5-1 Table 5-1 Gears and gearing: Belgian shipments, exports, Imports, and apparent consumption, 1-8 Year Shipments Exports Imports Apparent consumption Ratio (percent) of imports to consumption Value (million dollars) 1 4.7 3.9 1.2 3.0 6.3 1 5.1 4.2 2.3 3.2 6.5 1 7.8 6.2 3.8 4.5 7.8 1 8.9 7.0 3.5 5.5 7.1 1 1,0.4 6.7 4.9 8.6 5.1 Value (million francs)

most of whom are in the automotive sector. Hourly compensation costs for production workers in industrial and commercial machinery manufacturing (SIC rose 1 percent during 1-8, from 5.5 Belgian francs in 1 to 5.3 Belgian francs in 1. In dollars, hourly compensation costs grew nearly 7 percent, from $9.0 in 1 to $1.7 in 1. 8 Most workers in the gear industry are unionized. According to industry officials, the union restricts employers' flexibility in the areas of layoffs and the number of hours worked. (") USITC staff interviews with gear industry officials, BelgiusaNtaofvoermber 1 1not Yet available. Unpublished data from the .. Bureau of Labor Statistics, August 1. Table 8-1 Leading Belgian gear producers, by major sectors, 1 Company Vehicle Industrial Marine Aerospace ABT Asco Clark Components CMI Transmissions David Brown Sad Defawes Esco Transmissions Ford Tractor Hansen Transmissions int' Twin Disc Volvo Cars Watteeuw Source: Fabrimetal. 5-1 Table 5-1 Gears and gearing: Belgian shipments, exports, Imports, and apparent consumption, 1-8 Year Shipments Exports Imports Apparent consumption Ratio (percent) of imports to consumption Value (million dollars) 1 4.7 3.9 1.2 3.0 6.3 1 5.1 4.2 2.3 3.2 6.5 1 7.8 6.2 3.8 4.5 7.8 1 8.9 7.0 3.5 5.5 7.1 1 1,0.4 6.7 4.9 8.6 5.1 Value (million francs)| Model Type | Helical gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Corporation |

| Country of Manufacture | Finland |

| Data Sheet & Drawings | H4-VH-15-D e maximum productivity energy efficiency and Helical gearbox H4 |