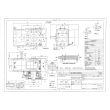

H4VH-14-C d optimally interacting with one another as a st Helical gear reducers H4

In stock

SKU

H4VH-14-C

$35,892.86

Flender/Flender Gear Units/Helical gear reducers H4

Forschung und Entwicklung mbH Ludwigshafener Strasse, 5 Wesseling Government sponsorship: DM 2,9,4 6 Sponsorship ratio: 3% 1. Purpose of the project In the first project phase (0 ZH, the hydrogenisability of various carbon-bearing wastes, such as plastic wastes, liquid organochemical

project In the first project phase (0 ZH, the hydrogenisability of various carbon-bearing wastes, such as plastic wastes, liquid organochemical  wastes, paint and surface coating residues to produce valuable oils suitable for numerous applications was displayed in autoclave tests. In

wastes, paint and surface coating residues to produce valuable oils suitable for numerous applications was displayed in autoclave tests. In  the second project phase, the technical feasibility of the hydrogenation process was to be proven by means of continuous trials

the second project phase, the technical feasibility of the hydrogenation process was to be proven by means of continuous trials  on pilot-plant scale. The goal of the trials to be conduct- ed was to gain the essential data for problem-free operation of pilot plantas regards thermo- chemical pretreatment, pressure and temperature in the hydrogenation reactor, as well as questions relating to materials. Investigations independent of the operation of the plant were intended to contribute to the develo ment of conceptsforthe mechanical pretreatment of the feedstocks, the feed system, as wel?as the utilisation and/or disposal of the hydrogenation residues.. In the event of the entire project being successful, the hydrogenation process was intended to fill an existing ap in the reutilisation of wastes and to make considerable contribution towards,the rejuction of environmental pollution and conservation of resources. 2. Working steps The main aspects of the working programme were as follows - Investigations into the mechanical reprocessing of authentic plastic wastes - Conversion and expansion of pilot plant to meet the specific demands of chlorine-bearing organochemical wastes - Operation of the pilot plant with model and authentic mixtures, in order to transfer the fundamental knowledge to continuous operation, optimise the operating conditions, verify heteroatomic decomposition and perform material tests - Concomitant laboratory work, in particular balancing of the continuous trial runs, catalyst tests and laboratory te

on pilot-plant scale. The goal of the trials to be conduct- ed was to gain the essential data for problem-free operation of pilot plantas regards thermo- chemical pretreatment, pressure and temperature in the hydrogenation reactor, as well as questions relating to materials. Investigations independent of the operation of the plant were intended to contribute to the develo ment of conceptsforthe mechanical pretreatment of the feedstocks, the feed system, as wel?as the utilisation and/or disposal of the hydrogenation residues.. In the event of the entire project being successful, the hydrogenation process was intended to fill an existing ap in the reutilisation of wastes and to make considerable contribution towards,the rejuction of environmental pollution and conservation of resources. 2. Working steps The main aspects of the working programme were as follows - Investigations into the mechanical reprocessing of authentic plastic wastes - Conversion and expansion of pilot plant to meet the specific demands of chlorine-bearing organochemical wastes - Operation of the pilot plant with model and authentic mixtures, in order to transfer the fundamental knowledge to continuous operation, optimise the operating conditions, verify heteroatomic decomposition and perform material tests - Concomitant laboratory work, in particular balancing of the continuous trial runs, catalyst tests and laboratory te| Model Type | Helical gear reducers H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1675.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | Egypt |

| Data Sheet & Drawings | H4VH-14-C d optimally interacting with one another as a st Helical gear reducers H4 |