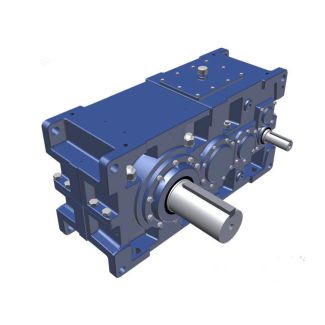

H4-VV-26B They are preferred for use in systems that are p Helical speed reduction gearbox H4

In stock

SKU

H4-VV-26B

$210,000.00

Flender/Flender Gear Units/Helical speed reduction gearbox H4

Germany on raw material imports leads to situation where raw materials which lave low metal content or are difficult to process increasingly have to be used for the production of non-ferrous metals. In addition, the metallurgical pro- cessing of intermediate

process increasingly have to be used for the production of non-ferrous metals. In addition, the metallurgical pro- cessing of intermediate  products, sludges, ashes and dusts, residuesfrom recycling processes, various types of precipitation products, etc. is becoming increasingly important. The goal

products, sludges, ashes and dusts, residuesfrom recycling processes, various types of precipitation products, etc. is becoming increasingly important. The goal  of this & project was to develop low-emission technologies for processing raw materials of low quality or complex com osition,

of this & project was to develop low-emission technologies for processing raw materials of low quality or complex com osition,  so that the metallic components and mater- ials can either be extracted directly by ~ydrometallurgicalielectrometallurgical methods, or converted into form which allows them to be easily channelled into existing metallurgical processes.ThisR& project included thestudy of numerous primaryandsecondaryrawmate- rials, as well as various process steps, with the goal of developing closed metallurgical material cycles with low environmental loads requiring minimum chemical and energy input. 2. Working steps Metallur ical studies must always be carried out in conjunction with chemical and analytical controls,%ecause the effect of changes in individual process parameters can only be assessed in this way. Thus, analytical work is priority in this project. The ex eriments with the raw materials mentioned include hydrometallur icaland rometal- lurgicayprocess steps which are primarily carried out in the laboratory an3 in individal cases, also on pilot scale. The purpose of the pyrometallurgical investigations is to use targeted oxi- dation or reduction to arriveat separation or enrichment processes which are of greattechnical and economical importance for the processing of low-grade and complex raw materials. The hydrometallurgical work includes selectivity studies in connection with storage processes, redox reactions, lye purification tests including solid-liquid separation, anodic and cathodic electrolysis pr

so that the metallic components and mater- ials can either be extracted directly by ~ydrometallurgicalielectrometallurgical methods, or converted into form which allows them to be easily channelled into existing metallurgical processes.ThisR& project included thestudy of numerous primaryandsecondaryrawmate- rials, as well as various process steps, with the goal of developing closed metallurgical material cycles with low environmental loads requiring minimum chemical and energy input. 2. Working steps Metallur ical studies must always be carried out in conjunction with chemical and analytical controls,%ecause the effect of changes in individual process parameters can only be assessed in this way. Thus, analytical work is priority in this project. The ex eriments with the raw materials mentioned include hydrometallur icaland rometal- lurgicayprocess steps which are primarily carried out in the laboratory an3 in individal cases, also on pilot scale. The purpose of the pyrometallurgical investigations is to use targeted oxi- dation or reduction to arriveat separation or enrichment processes which are of greattechnical and economical importance for the processing of low-grade and complex raw materials. The hydrometallurgical work includes selectivity studies in connection with storage processes, redox reactions, lye purification tests including solid-liquid separation, anodic and cathodic electrolysis pr| Model Type | Helical speed reduction gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | Barbados |

| Data Sheet & Drawings | H4-VV-26B They are preferred for use in systems that are p Helical speed reduction gearbox H4 |