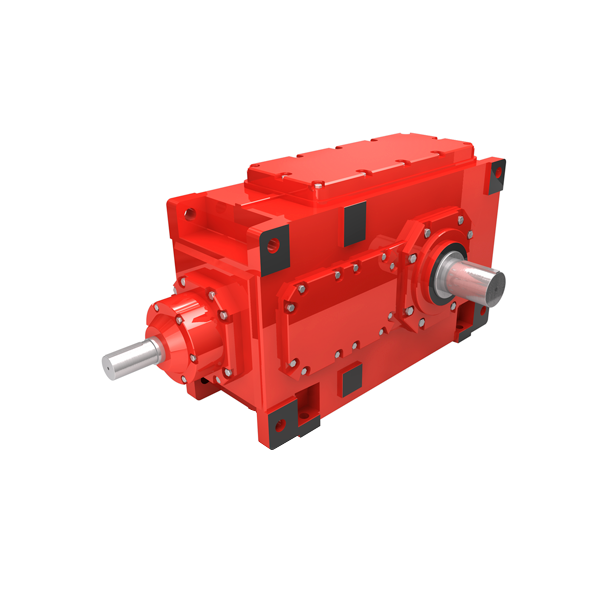

H4VV-27-C from the motor or driven machine Nominal output Helical gear reducers H4

In stock

SKU

H4VV-27-C

$254,571.43

Flender/Flender Gear Units/Helical gear reducers H4

gh performance according to specic requirements for any size of corn. The rotor speed can also be adjusted to Fig. 1 Side view of Beall degerminator. (Courtesy of the Beall Degerminator Co.) Specialty Milling 3 desired level. The rotor is

1 Side view of Beall degerminator. (Courtesy of the Beall Degerminator Co.) Specialty Milling 3 desired level. The rotor is  provided with chilled iron knob surface to resist wear. The rotor itself is made up of ve sections; therefore, in

provided with chilled iron knob surface to resist wear. The rotor itself is made up of ve sections; therefore, in  case of wear rather than replacingthe whole rotor, only the section with wear is replaced. 2.3 Common Degermination and Milling

case of wear rather than replacingthe whole rotor, only the section with wear is replaced. 2.3 Common Degermination and Milling  Practices Dry milling of corn can be carried out in many different ways. Some of the commonly used commercial practices will be described next. All of these processes involve removalof germ and hull. If the germ is not required to be removed then the milling processbecomes much simpler. The processes described are adaptations of practices in Europeand as well as in North America. One of the characteristic differences between the milling practices in the two continents is that in Europe there is much more use of puriers in the mill, whereas in North America the use of puriers is limited and the use of aspirators is more extensive. 2.3.1 Degermination and Milling with RollermillsThe milling equipment used in this process is similar to that used in wheat our mills. After cleaning and short tempering of corn to approximately 1.5.0% moisture it is sent to rst-break passage for grinding. There may be many different congurations of equipment that can be used with advantage to suit each specic situation. Generally, thereare four break passages, two sizing or scratch system passages and four purication pas-sages. Aspirators are used in many different locations in the milling section for removalof hulls, for they are created each time some processing takes place. The aspirators arelocated ahead of second-, third-, and fourth-break passages (Fig. . Table 8 provides some technical specications for the rolls and corrugations. Table 9 provides an indication of surface allocation required by this type of m

Practices Dry milling of corn can be carried out in many different ways. Some of the commonly used commercial practices will be described next. All of these processes involve removalof germ and hull. If the germ is not required to be removed then the milling processbecomes much simpler. The processes described are adaptations of practices in Europeand as well as in North America. One of the characteristic differences between the milling practices in the two continents is that in Europe there is much more use of puriers in the mill, whereas in North America the use of puriers is limited and the use of aspirators is more extensive. 2.3.1 Degermination and Milling with RollermillsThe milling equipment used in this process is similar to that used in wheat our mills. After cleaning and short tempering of corn to approximately 1.5.0% moisture it is sent to rst-break passage for grinding. There may be many different congurations of equipment that can be used with advantage to suit each specic situation. Generally, thereare four break passages, two sizing or scratch system passages and four purication pas-sages. Aspirators are used in many different locations in the milling section for removalof hulls, for they are created each time some processing takes place. The aspirators arelocated ahead of second-, third-, and fourth-break passages (Fig. . Table 8 provides some technical specications for the rolls and corrugations. Table 9 provides an indication of surface allocation required by this type of m| Model Type | Helical gear reducers H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 11880.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | Bolivia |

| Data Sheet & Drawings | H4VV-27-C from the motor or driven machine Nominal output Helical gear reducers H4 |