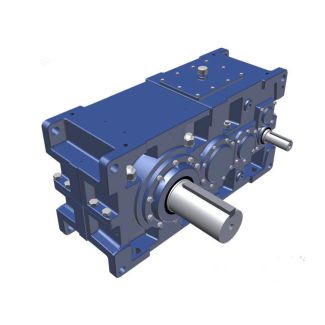

H4-VV-26-D NmFlexible couplings Our elastic couplings are p Helical gear units H4

In stock

SKU

H4-VV-26-D

$210,000.00

Flender/Flender Gear Units/Helical gear units H4

ges per dayas mitigated by the proximity of the trap to the site of emanations. In large storageroom, grid of traps would be necessary to permit determination of the position of theinfection locus. The size of the storage facility, the

traps would be necessary to permit determination of the position of theinfection locus. The size of the storage facility, the  mass of produce stored, the level of infection, the emanation rate of volatiles, the free air space, and the ventilation

mass of produce stored, the level of infection, the emanation rate of volatiles, the free air space, and the ventilation  requirements allcome into play in evaluating the feasibility of volatile monitoring as disease detectiontechnique. The less free volume there is,

requirements allcome into play in evaluating the feasibility of volatile monitoring as disease detectiontechnique. The less free volume there is,  the greater the concentration of volatile emittedby given mass of infected produce. Furthermore, since there is more produce when thefree air space is small, this greater concentration is representative of lower percentage of infected produce even though the infected mass is the same. The unknown at this point is the rate of emanation of volatiles. 5.2 Estimation of Volatile Emanation Rates of Potatoes The respiration rate of potatoes stored at 5 C1C is in the range of about 1 to 1 mg CO 2kg/H1day/H1(. Although volatile emanation rates have never been quantied for stored potatoes, whether healthy or diseased, they can be estimated on the basis of data on apples and pears obtained by cerate oxidimetry (. Respiration rates of applesstored at /H1.5C were about 8 mg CO 2kg/H1day/H1, or slightly lower than potatoes at 5C1C. Nonethylene volatile emanation rates for apples were reported in terms of milligrams Ce(SO 2-reduced kg/H1day/H1; rates ranged from 1 at the beginning of storage Volatile Monitoring in Storage 6 to 5 for McIntosh apples and 2 for Golden Delicious by 1 days. Assuming an average molecular weight of volatiles of 1 and stoichiometric ratio of 2.5:1 in the reductionreactions, the volatile production rates ranged from 0.1 to about 3 mg kg /H1day/H1, ro the order of 3% of the CO 2emanations. When fruits were removed from storage and allowed to ripen at 1 , respiration increased by 5 to 6 times and production of noneth- ylene volatiles increased 1- to

the greater the concentration of volatile emittedby given mass of infected produce. Furthermore, since there is more produce when thefree air space is small, this greater concentration is representative of lower percentage of infected produce even though the infected mass is the same. The unknown at this point is the rate of emanation of volatiles. 5.2 Estimation of Volatile Emanation Rates of Potatoes The respiration rate of potatoes stored at 5 C1C is in the range of about 1 to 1 mg CO 2kg/H1day/H1(. Although volatile emanation rates have never been quantied for stored potatoes, whether healthy or diseased, they can be estimated on the basis of data on apples and pears obtained by cerate oxidimetry (. Respiration rates of applesstored at /H1.5C were about 8 mg CO 2kg/H1day/H1, or slightly lower than potatoes at 5C1C. Nonethylene volatile emanation rates for apples were reported in terms of milligrams Ce(SO 2-reduced kg/H1day/H1; rates ranged from 1 at the beginning of storage Volatile Monitoring in Storage 6 to 5 for McIntosh apples and 2 for Golden Delicious by 1 days. Assuming an average molecular weight of volatiles of 1 and stoichiometric ratio of 2.5:1 in the reductionreactions, the volatile production rates ranged from 0.1 to about 3 mg kg /H1day/H1, ro the order of 3% of the CO 2emanations. When fruits were removed from storage and allowed to ripen at 1 , respiration increased by 5 to 6 times and production of noneth- ylene volatiles increased 1- to| Model Type | Helical gear units H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | Belgium |

| Data Sheet & Drawings | H4-VV-26-D NmFlexible couplings Our elastic couplings are p Helical gear units H4 |