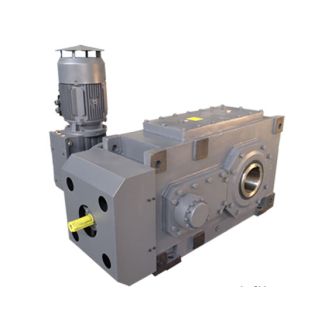

H4-VH-17-A ons of our gear units from the target status The Helical gear Reduction Box H4

In stock

SKU

H4-VH-17-A

$74,464.29

Flender/Flender Gear Units/Helical gear Reduction Box H4

friction hullers but use phosphorbronze bars, which are softer than steel and do not harm the beans. 3.6.2 Grading Grading is the separation of beans according to size and density. The coffee bean has three dimensions: length, width, and thickness.

is the separation of beans according to size and density. The coffee bean has three dimensions: length, width, and thickness.  It is usually oblong, fairly at, and boatshaped. However, peaberry has an elongated oval shape. Although round perforations are sufcient

It is usually oblong, fairly at, and boatshaped. However, peaberry has an elongated oval shape. Although round perforations are sufcient  to separate most beans, peaberry requires oblong slots. at bed grader and drum grader separate the beans according to size,

to separate most beans, peaberry requires oblong slots. at bed grader and drum grader separate the beans according to size,  and pneumatic separators, often calledcatadors , grade the beans by density (Figs. 1, . It must be noted that in grading of coffee, lot can be labeled only as Graded and Garbled or as Bulk. It must be ensured that standards (of percentage range ofBlacks) specied for grading lot as Graded and Garbled, Bulk, or Blacksare strictly observed. The sieving standards for different types and grades of coffee should also be strictly enforced. Screen (sieve) sizes are expressed as numbers, .., Robusta Grade One Screen 1; or by letters, .., Arabica Grade AA for bold bean, or by descrip-tion, .., bold, medium, or small. Grading depends on trade custom in any given country.However, all coffee for export is graded to exclude the largest and smallest beans andparticles (. Coffee Processing 7 Fig. 9 Construction details of the Okrassa huller-polisher, showing the two separate compart- ments: ( huller, ( polisher. (From Ref. 1. Reproduced with permission.) Fig. 1 Grading of coffee beans. (Courtesy of Chamundi Coffee Curing Works, Mysore, India.) 7 Ramalakshmi and Raghavan Fig. 1 Peaberry separator. (Courtesy of Chamundi Coffee Curing Works, Mysore, India.) The Indian grade designations and standards for Coffea arabica andC. robusta are listed in Table 6. 3.6.3 Sorting Sorting is usually the nal stage in the preparation of coffee for export. It is required to remove any defective bean remaining after processing. certain amount of extraneousmaterial, including whole berri

and pneumatic separators, often calledcatadors , grade the beans by density (Figs. 1, . It must be noted that in grading of coffee, lot can be labeled only as Graded and Garbled or as Bulk. It must be ensured that standards (of percentage range ofBlacks) specied for grading lot as Graded and Garbled, Bulk, or Blacksare strictly observed. The sieving standards for different types and grades of coffee should also be strictly enforced. Screen (sieve) sizes are expressed as numbers, .., Robusta Grade One Screen 1; or by letters, .., Arabica Grade AA for bold bean, or by descrip-tion, .., bold, medium, or small. Grading depends on trade custom in any given country.However, all coffee for export is graded to exclude the largest and smallest beans andparticles (. Coffee Processing 7 Fig. 9 Construction details of the Okrassa huller-polisher, showing the two separate compart- ments: ( huller, ( polisher. (From Ref. 1. Reproduced with permission.) Fig. 1 Grading of coffee beans. (Courtesy of Chamundi Coffee Curing Works, Mysore, India.) 7 Ramalakshmi and Raghavan Fig. 1 Peaberry separator. (Courtesy of Chamundi Coffee Curing Works, Mysore, India.) The Indian grade designations and standards for Coffea arabica andC. robusta are listed in Table 6. 3.6.3 Sorting Sorting is usually the nal stage in the preparation of coffee for export. It is required to remove any defective bean remaining after processing. certain amount of extraneousmaterial, including whole berri| Model Type | Helical gear Reduction Box H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 3475.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender (Australia) Pty. Ltd. |

| Country of Manufacture | China |

| Data Sheet & Drawings | H4-VH-17-A ons of our gear units from the target status The Helical gear Reduction Box H4 |