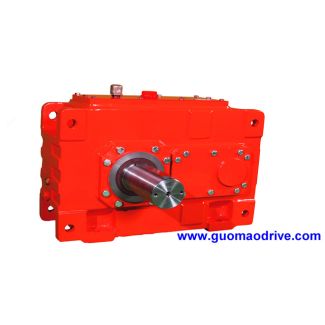

H4-KH-22-D emperature of C and a maximum cooling water t Helical speed reduction gearbox H4

In stock

SKU

H4-KH-22-D

$173,571.43

Flender/Flender Gear Units/Helical speed reduction gearbox H4

ion in 1 to $7.7 million in 1, 4-percent gain, but did not keep pace with such expenditures by broader industry groups (. 4-. Gear industry & expenditures represented less than 1 percent of shipments during 1-8 whereas the level

industry groups (. 4-. Gear industry & expenditures represented less than 1 percent of shipments during 1-8 whereas the level  of & for nonelectrical machinery industries, similar but broader group, totaled 3.5 percent of sales in 1. University gear research

of & for nonelectrical machinery industries, similar but broader group, totaled 3.5 percent of sales in 1. University gear research  in the United States has lagged behind that performed in West Germany and Japan. Traditionally, the bulk of gear &

in the United States has lagged behind that performed in West Germany and Japan. Traditionally, the bulk of gear &  in the United States is done at the company level and is generally not shared. Several ongoing projects in the United States, especially the work of the ASME Gear Research Institute and the Defense Logistics Agency' newly established Instrumented Factory for Gears (INFAC), are designed to improve the competitive position of the .. gear industry (. 4-1, table ). II. Profile of major foreign gear industries The Japanese gear industry had shipments of $8.4 billion in 1 and employed an estimated 3,0 persons. Japan' gear industry shipments were predominantly motor vehicle gearing, with the bulk of the remainder accounted for by industrial and marine gearing. Japan' aerospace gearing industry is relatively small, but is growing through licensing agreements for larger components, such as engines, and through co-production of aircraft with .. and Western European aerospace producers. In 1, the Japanese gear industry served domestic market estimated at $6.0 billion, and its exports totaled an estimated $2.5 billion. Approximately 8 percent of exports were of vehicle gearing. Imports of gearing products totaled just $9 million and consisted mainly of industrial and vehicle gearing. Major foreign suppliers were the United States, France, and West Germany (. 5-. The West German gear industry had shipments of $4.8 billion in 1 and employed an estimated 2.3,0 persons. West Germany is technological leader in industrial gearing in contrast with other major producers, shipments of

in the United States is done at the company level and is generally not shared. Several ongoing projects in the United States, especially the work of the ASME Gear Research Institute and the Defense Logistics Agency' newly established Instrumented Factory for Gears (INFAC), are designed to improve the competitive position of the .. gear industry (. 4-1, table ). II. Profile of major foreign gear industries The Japanese gear industry had shipments of $8.4 billion in 1 and employed an estimated 3,0 persons. Japan' gear industry shipments were predominantly motor vehicle gearing, with the bulk of the remainder accounted for by industrial and marine gearing. Japan' aerospace gearing industry is relatively small, but is growing through licensing agreements for larger components, such as engines, and through co-production of aircraft with .. and Western European aerospace producers. In 1, the Japanese gear industry served domestic market estimated at $6.0 billion, and its exports totaled an estimated $2.5 billion. Approximately 8 percent of exports were of vehicle gearing. Imports of gearing products totaled just $9 million and consisted mainly of industrial and vehicle gearing. Major foreign suppliers were the United States, France, and West Germany (. 5-. The West German gear industry had shipments of $4.8 billion in 1 and employed an estimated 2.3,0 persons. West Germany is technological leader in industrial gearing in contrast with other major producers, shipments of| Model Type | Helical speed reduction gearbox H4 |

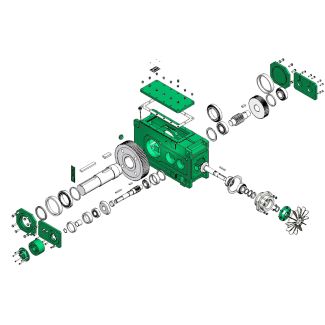

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Ibérica S.A. |

| Country of Manufacture | Romania |

| Data Sheet & Drawings | H4-KH-22-D emperature of C and a maximum cooling water t Helical speed reduction gearbox H4 |