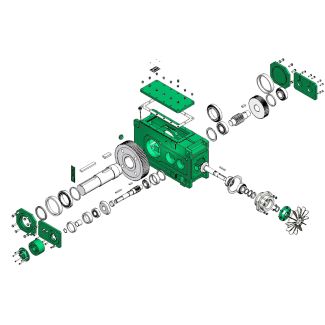

H4-KH-23-D nit with cooling coil adequate Fan and cooling c Helical gear boxes H4

In stock

SKU

H4-KH-23-D

$195,000.00

Flender/Flender Gear Units/Helical gear boxes H4

ion of dehulling of pigeon pea with different pre-treatments and conditions. Food Sci Technol 3:4. 2. Prasoon Verma, Saxena RP, Sarkar BC, Omre PK (. Enzymatic pretreatment of pigeon pea grains and its interaction with milling. Food Sci Technol 3:3.

Sarkar BC, Omre PK (. Enzymatic pretreatment of pigeon pea grains and its interaction with milling. Food Sci Technol 3:3.  2. Ramakrishnaiah , Kurien PP (. Variabilities in the dehulling characteristics of pigeon pea cultivars. Food Sci Technol 2:2. 2.

2. Ramakrishnaiah , Kurien PP (. Variabilities in the dehulling characteristics of pigeon pea cultivars. Food Sci Technol 2:2. 2.  Ramakrishnaiah , Kurien PP (. Nonstarchy polysaccharides of pigeon pea and their inuence on dehulling characteristics. Food Sci Technol 2:4.

Ramakrishnaiah , Kurien PP (. Nonstarchy polysaccharides of pigeon pea and their inuence on dehulling characteristics. Food Sci Technol 2:4.  3. Ramakrishnaiah , Pratape VM, Narasimha HV (. National survey of pulse milling in- dustry in India including rural processing, status report, Central Food Technological ResearchInstitute, Mysore, India. 3. Ramakrishnaiah , Pratape VM, Kurien PP (. Central Food Technological Research Institute, Mysore, India. Unpublished data. 3. Ramakrishnaiah , Kurien PP (. Non starchy polysaccharides content of desi and kabuli varieties of chickpea. Central Food Technological Research Institute, Mysore, India, AnnualReport. 3. Reichert RD, Young CG (. Dehulling cereal grains and grain legumes for developing countries. 1. Quantitative comparison between attrition and abrasive type mills. Cereal Chem 5:8. 3. Reichert RD, Lorer EF, Youngs CG (. Village scale mechanical dehulling of cowpea. Cereal Chem 5:1. 3. Reichert RD, Ooman BD, Young CG (. Factors affecting the efciency of abrasive type dehulling of grain legumes investigated with new batch dehuller. Food Sci Technol 4:2. 3. Reichert RD, Tyler RT, York AE, Schwab DJ, Tatarynovich JE, Mwasaru MA (. De- scription of production model or tangential abrasive dehulling device (TADD) and its appli-cation to breeders samples. Cereal Chem 6:2. 3. Sahay KM, Bisht BS (. Development of small abrasive cylindrical mill for milling pulses. Int Food Sci Technol 2:1. 3. Sahay KM (. Evaluation of general purpose abrasive mill for dehulling of pulses. Int Food Sci Technol 2:2. 3. Saxena RP, Laxmi Cha

3. Ramakrishnaiah , Pratape VM, Narasimha HV (. National survey of pulse milling in- dustry in India including rural processing, status report, Central Food Technological ResearchInstitute, Mysore, India. 3. Ramakrishnaiah , Pratape VM, Kurien PP (. Central Food Technological Research Institute, Mysore, India. Unpublished data. 3. Ramakrishnaiah , Kurien PP (. Non starchy polysaccharides content of desi and kabuli varieties of chickpea. Central Food Technological Research Institute, Mysore, India, AnnualReport. 3. Reichert RD, Young CG (. Dehulling cereal grains and grain legumes for developing countries. 1. Quantitative comparison between attrition and abrasive type mills. Cereal Chem 5:8. 3. Reichert RD, Lorer EF, Youngs CG (. Village scale mechanical dehulling of cowpea. Cereal Chem 5:1. 3. Reichert RD, Ooman BD, Young CG (. Factors affecting the efciency of abrasive type dehulling of grain legumes investigated with new batch dehuller. Food Sci Technol 4:2. 3. Reichert RD, Tyler RT, York AE, Schwab DJ, Tatarynovich JE, Mwasaru MA (. De- scription of production model or tangential abrasive dehulling device (TADD) and its appli-cation to breeders samples. Cereal Chem 6:2. 3. Sahay KM, Bisht BS (. Development of small abrasive cylindrical mill for milling pulses. Int Food Sci Technol 2:1. 3. Sahay KM (. Evaluation of general purpose abrasive mill for dehulling of pulses. Int Food Sci Technol 2:2. 3. Saxena RP, Laxmi Cha| Model Type | Helical gear boxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9100.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 640000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Corporation |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-KH-23-D nit with cooling coil adequate Fan and cooling c Helical gear boxes H4 |