H4-HV-8B quality considerably more resistant to impacts Helical speed reduction gearbox H4

In stock

SKU

H4-HV-8B

$546,428.57

Flender/Flender Gear Units/Helical speed reduction gearbox H4

ial for safe and reliable torque transmission. Do not use contaminated solvents or dirty cloths for removing grease. Put the gear unit on the counterflange with the aid of suitable lifting gear. Tighten flange bolts. Tighten the flange bolts crosswise

gear unit on the counterflange with the aid of suitable lifting gear. Tighten flange bolts. Tighten the flange bolts crosswise  with the full tightening torque. The joint bolts must be tightened to the prescribed torque. For the correct torque, refer

with the full tightening torque. The joint bolts must be tightened to the prescribed torque. For the correct torque, refer  to item 6.2. Bolts of the minimum strength class 8.8 must be used. The transmittable tensioning torque is limited by

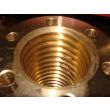

to item 6.2. Bolts of the minimum strength class 8.8 must be used. The transmittable tensioning torque is limited by  the bolted joint on bolt circle 1. The gear unit must not be excessively stressed when tensioning the fastening bolts. 6.5.2.2 Assembly of agitator gear units with hollow output shaft (types .TV and .JV) 2 1K1d3K1d3 .TV .JV Fig. 5: Agitator gear unit of types .TV and .JV 1 Mounting flange 2 Block flange The mounting or blocktype flange on the output side of agitator gear units is provided with centering shoulder ( . If the machine shaft is supported on one side only, .. the gear unit takes over as the 2nd bearing location, the counterflange on the machine side has to be provided with bore (fit H which matches the centering shoulder. In the case of machine shaft which is double supported in the counterflange on the machine side, centering of the agitator gear unit (centering shoulder in the counterflange is inadmissible (redundancy). When aligning the machine shaft in relation to the counterflange, the radial and angular misalignments should be kept as small as possible. The service life of the shaft and bearings within the gear unit largely depends on the aligning accuracy of the machine shaft in relation to the counterflange. If possible, the deviation should be zero. For permissible tolerances please refer to the drawings in the gear unit documentation. Clean the supporting surface of the mounting or blocktype flange of the gear unit and the counterflange on the machine side. The front area of the mounting flange and counterflange must be absolutely free from greas

the bolted joint on bolt circle 1. The gear unit must not be excessively stressed when tensioning the fastening bolts. 6.5.2.2 Assembly of agitator gear units with hollow output shaft (types .TV and .JV) 2 1K1d3K1d3 .TV .JV Fig. 5: Agitator gear unit of types .TV and .JV 1 Mounting flange 2 Block flange The mounting or blocktype flange on the output side of agitator gear units is provided with centering shoulder ( . If the machine shaft is supported on one side only, .. the gear unit takes over as the 2nd bearing location, the counterflange on the machine side has to be provided with bore (fit H which matches the centering shoulder. In the case of machine shaft which is double supported in the counterflange on the machine side, centering of the agitator gear unit (centering shoulder in the counterflange is inadmissible (redundancy). When aligning the machine shaft in relation to the counterflange, the radial and angular misalignments should be kept as small as possible. The service life of the shaft and bearings within the gear unit largely depends on the aligning accuracy of the machine shaft in relation to the counterflange. If possible, the deviation should be zero. For permissible tolerances please refer to the drawings in the gear unit documentation. Clean the supporting surface of the mounting or blocktype flange of the gear unit and the counterflange on the machine side. The front area of the mounting flange and counterflange must be absolutely free from greas| Model Type | Helical speed reduction gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 25500.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Ibérica S.A. |

| Country of Manufacture | Saudi Arabia |

| Data Sheet & Drawings | H4-HV-8B quality considerably more resistant to impacts Helical speed reduction gearbox H4 |