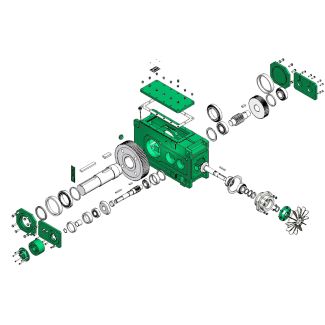

H4-HV9-B y Considerably lower risk of damage to the color Helical gear boxes H4

In stock

SKU

H4-HV9-B

$6,857.14

Flender/Flender Gear Units/Helical gear boxes H4

ials could be manufactured on ilot plant scale, takin into consideration the material nufacture of the powders and their further processing 3.2.1 Powder manufacture The development work for converting owder metallur manufacturing process for cad- mium-free silver contact materials from

processing 3.2.1 Powder manufacture The development work for converting owder metallur manufacturing process for cad- mium-free silver contact materials from  tffe laboratory sca? to the pilot plant scale was con- ducted by Dornier-System in rojects 0VQ0 and OlVQ8 One essential

tffe laboratory sca? to the pilot plant scale was con- ducted by Dornier-System in rojects 0VQ0 and OlVQ8 One essential  goal of the work comprised testing the beRaviour ofthe reactor and its associated peripheral components in steady-state operation In this

goal of the work comprised testing the beRaviour ofthe reactor and its associated peripheral components in steady-state operation In this  context, operating experience with the throughput of large quantities of solutions was to be collected, in particular After clarification of the rocess engineering boundary conditions, daily throughputs of up to 6 kg powder were ac\ieved The characteristic data for the steady-state operation of the AgX reactor are given in the fol- lowing overview qualities demanded by the market In $tail, the working goa 7 were geared towards the ma- Solution throughput: Yield: Nozzle: Compressed air consumption: Nozzle pressure: Metering pump pressure: Cleaning: Electrical power consumption: Cooling water throughput: 1 to 1 / 9 (AgSnO,) 4.9 kg/ 9% (AaNi) 6.9 ka/ CSLA hd, 5 m3/8 (CSL) Monosubstance AgNi 1 bar (CSL) 1 bar Rapper and vibrating roller 4 kW 0.7 m3/ 2 3.2.2 Further processing of the powder, testing of the switching properties INOVAN primarily tested the methods for further processing into semi-finished parts and indi- vidual contact ieces In this context, the metal powders pre-compressed into so-called blanks had to be furtEer pressed almost up to their theoretical material density. This was achieved through sinter annealing below the melting point of silver and subsequent pressing, for . example. The contact material thus compressed was subsequently rolled into sheets or strips or drawn into wire. Because the oxidic contact material silver tin oxide is difficult to solder and weld, these cont

context, operating experience with the throughput of large quantities of solutions was to be collected, in particular After clarification of the rocess engineering boundary conditions, daily throughputs of up to 6 kg powder were ac\ieved The characteristic data for the steady-state operation of the AgX reactor are given in the fol- lowing overview qualities demanded by the market In $tail, the working goa 7 were geared towards the ma- Solution throughput: Yield: Nozzle: Compressed air consumption: Nozzle pressure: Metering pump pressure: Cleaning: Electrical power consumption: Cooling water throughput: 1 to 1 / 9 (AgSnO,) 4.9 kg/ 9% (AaNi) 6.9 ka/ CSLA hd, 5 m3/8 (CSL) Monosubstance AgNi 1 bar (CSL) 1 bar Rapper and vibrating roller 4 kW 0.7 m3/ 2 3.2.2 Further processing of the powder, testing of the switching properties INOVAN primarily tested the methods for further processing into semi-finished parts and indi- vidual contact ieces In this context, the metal powders pre-compressed into so-called blanks had to be furtEer pressed almost up to their theoretical material density. This was achieved through sinter annealing below the melting point of silver and subsequent pressing, for . example. The contact material thus compressed was subsequently rolled into sheets or strips or drawn into wire. Because the oxidic contact material silver tin oxide is difficult to solder and weld, these cont| Model Type | Helical gear boxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 320.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Corporation |

| Country of Manufacture | Slovakia |

| Data Sheet & Drawings | H4-HV9-B y Considerably lower risk of damage to the color Helical gear boxes H4 |