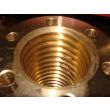

H4HV-8-C scratches and abrasions Can be immediately used Helical gear Reduction Box H4

In stock

SKU

H4HV-8-C

$546,428.57

Flender/Flender Gear Units/Helical gear Reduction Box H4

ial requirements. Use our online configurator, which allows you to create tailored product combinations.INDIVIDUAL SOLUTIONS. /1 GREAT EXPERTISE IN YOUR INDUSTRY TOO. Each industry has its own conditions. Every application has its own specific requirements. We are looking forward to

INDUSTRY TOO. Each industry has its own conditions. Every application has its own specific requirements. We are looking forward to  meeting your challenges. We probably already have the right solution at hand. Here are few examples: Cement Plastics and rubber

meeting your challenges. We probably already have the right solution at hand. Here are few examples: Cement Plastics and rubber  Minerals and mining Requirement: Perfectly coordinated drive systemRequirement: Low maintenance effort and cost, sealing due to dirt in surroundingsRequirement: Absorption

Minerals and mining Requirement: Perfectly coordinated drive systemRequirement: Low maintenance effort and cost, sealing due to dirt in surroundingsRequirement: Absorption  of high axial forces, suitability for explosion protection Industrial cranes Pulp and paper Environmental and recycling Requirement: Highest possible reliability, rugged designRequirement: Suitability for centrally located lubricationRequirement: Quick availability, version with double drive shaft /1 Chemicals Power generation Metals Requirement: Absorption of forces from the manufacturing processRequirement: Effective cooling, speed adjustment for motor to fanRequirement: Harsh working conditions, high peak loads Oil and gas Harbor cranes Requirement: Specific axle clearance, frequent start-upRequirement: Flexible adaptation to speed requirementsRequirement: Absorption of external forces, oil-retaining pipe requiredWater and wastewater /1 FLENDER SERVICES Enjoy the support of our service experts, from planning, development and operation to the modernization of your plant and benefit from our experience and in-depth know-how of your application in more than 1 countries, seven days week, 2 hours day. Reduce standstills, minimize downtimes due to failure, and increase the productivity, flexibility and cost efficiency of your plant.AN ORIGINAL FOR THE LONG TERM WITH ORIGINAL FLENDER SERVICES Ever increasing requirements make it more and more important for industrial plants to work with maximum productivity and efficiency. Flender Services

of high axial forces, suitability for explosion protection Industrial cranes Pulp and paper Environmental and recycling Requirement: Highest possible reliability, rugged designRequirement: Suitability for centrally located lubricationRequirement: Quick availability, version with double drive shaft /1 Chemicals Power generation Metals Requirement: Absorption of forces from the manufacturing processRequirement: Effective cooling, speed adjustment for motor to fanRequirement: Harsh working conditions, high peak loads Oil and gas Harbor cranes Requirement: Specific axle clearance, frequent start-upRequirement: Flexible adaptation to speed requirementsRequirement: Absorption of external forces, oil-retaining pipe requiredWater and wastewater /1 FLENDER SERVICES Enjoy the support of our service experts, from planning, development and operation to the modernization of your plant and benefit from our experience and in-depth know-how of your application in more than 1 countries, seven days week, 2 hours day. Reduce standstills, minimize downtimes due to failure, and increase the productivity, flexibility and cost efficiency of your plant.AN ORIGINAL FOR THE LONG TERM WITH ORIGINAL FLENDER SERVICES Ever increasing requirements make it more and more important for industrial plants to work with maximum productivity and efficiency. Flender Services| Model Type | Helical gear Reduction Box H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 25500.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | Serbia |

| Data Sheet & Drawings | H4HV-8-C scratches and abrasions Can be immediately used Helical gear Reduction Box H4 |