H4-DV23-B converter operation Min max frequency Hz Hz Amb Helical gear reducer H4

In stock

SKU

H4-DV23-B

$143,571.43

Flender/Flender Gear Units/Helical gear reducer H4

ing chamber. This difference of pressure and density creates conditions under which efciency is less thanoptimum because the upper portion of the milling chamber is underutilized. Thus, unevenpressure creates conditions for increases in broken grains. Rice Milling and Processing 3

of the milling chamber is underutilized. Thus, unevenpressure creates conditions for increases in broken grains. Rice Milling and Processing 3  Fig. 1 Cross section of vertical (top-down), abrasive-type rice-milling machine. Rice enters from the top of the machine and falls

Fig. 1 Cross section of vertical (top-down), abrasive-type rice-milling machine. Rice enters from the top of the machine and falls  into milling chamber, which consists of abrasive rolls rotating within perforated metal screens. Milled rice is discharged from the bottom

into milling chamber, which consists of abrasive rolls rotating within perforated metal screens. Milled rice is discharged from the bottom  outlet. (Courtesy of Satake Corp.) To overcome the aforementioned drawbacks, vertical-milling machines, such as shown in Figs. 1 and 1, have been developed. These are of two typesnamely, the high- speed abrasive-type and the low-speed friction-typeand these are utilized in combined abrasive-type and friction-type system. The main features of these machines are that theshaft and milling chamber are vertically oriented and the ow of rice is in vertical Fig. 1 Cross section of vertical (bottom-up), friction-type rice-milling machine. Rice entering the inlet is conveyed horizontally by feeding screw, where it comes into contact with feed rolland is propelled upward into milling chamber consisting of steel milling roll rotating within perforated metal screens. Milled rice is forced from the top of the machine and is discharged through the outlet. (Courtesy of Satake Corp.) 3 Satake direction. The interaction of pressure and weight through all layers of rice within the chamber achieves maximum utilization of the milling surfaces, thus enhancing efciencyas well as preventing uneven pressures and the excess pressure that causes broken grains.In this way, higher-milling efciency and higher-milling yields with fewer broken grainscan be achieved. By combining the vertical high-speed abrasive-type with the vertical low-speed friction-type machines, an improved system can be evolved for almost any type of rice.For the Japonica sh

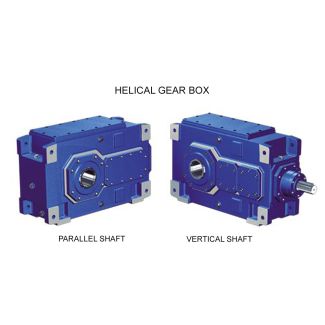

outlet. (Courtesy of Satake Corp.) To overcome the aforementioned drawbacks, vertical-milling machines, such as shown in Figs. 1 and 1, have been developed. These are of two typesnamely, the high- speed abrasive-type and the low-speed friction-typeand these are utilized in combined abrasive-type and friction-type system. The main features of these machines are that theshaft and milling chamber are vertically oriented and the ow of rice is in vertical Fig. 1 Cross section of vertical (bottom-up), friction-type rice-milling machine. Rice entering the inlet is conveyed horizontally by feeding screw, where it comes into contact with feed rolland is propelled upward into milling chamber consisting of steel milling roll rotating within perforated metal screens. Milled rice is forced from the top of the machine and is discharged through the outlet. (Courtesy of Satake Corp.) 3 Satake direction. The interaction of pressure and weight through all layers of rice within the chamber achieves maximum utilization of the milling surfaces, thus enhancing efciencyas well as preventing uneven pressures and the excess pressure that causes broken grains.In this way, higher-milling efciency and higher-milling yields with fewer broken grainscan be achieved. By combining the vertical high-speed abrasive-type with the vertical low-speed friction-type machines, an improved system can be evolved for almost any type of rice.For the Japonica sh| Model Type | Helical gear reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 6700.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 640000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Power Transmission Inc. |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-DV23-B converter operation Min max frequency Hz Hz Amb Helical gear reducer H4 |