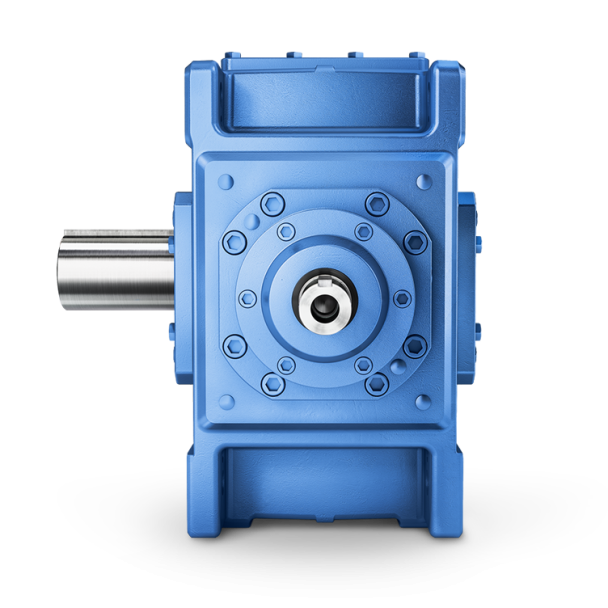

H4-DV-23-D eration Air humidity Operation in large halls Tem Helical speed reduction gearbox H4

In stock

SKU

H4-DV-23-D

$143,571.43

Flender/Flender Gear Units/Helical speed reduction gearbox H4

ing Dollies, one for enclosed, one for open bagasse storage 1 Fully Mechanized Enclosed Bagasse Storage, 1 4 , 7 of Usable Height, 6 Approximate Capacity 1 Moveable and Adjustable Bagasse Distribution and Reclaiming Rake (#, 1.5 1.4 , 0.8

of Usable Height, 6 Approximate Capacity 1 Moveable and Adjustable Bagasse Distribution and Reclaiming Rake (#, 1.5 1.4 , 0.8  /sec, 8 /, Chain Drive, Gearbox, 7.5 kW Motor, including Receiving Chute for Bagasse from Dolly on #3 2 Hoists

/sec, 8 /, Chain Drive, Gearbox, 7.5 kW Motor, including Receiving Chute for Bagasse from Dolly on #3 2 Hoists  for Vertical Displacement, 1 1 Transmission for 2 /min lengthwise Displacement Gearboxes, Motors 1 Drag-Type Conveyor below Grade (#, for

for Vertical Displacement, 1 1 Transmission for 2 /min lengthwise Displacement Gearboxes, Motors 1 Drag-Type Conveyor below Grade (#, for  Reclaiming Bagasse from Enclosed and Open Storage, 2.1 5 , 0.8 /sec, 8 /, Chain Drive, Gearbox, 4 kW Motor 1 Drag-Type Bagasse Return Conveyor (#, 2.1 3 , 0.8 /sec, 8 /, Inclined, Chain Drive, Gearbox, 3 kW Motor Drag-Type Bagasse Transfer Conveyor (#, 2.1 9 , 0.6 /sec, 8 /, Chain Drive, Gearbox, 5.5 kW Motor There is under construction drier that will use flue gases from boiler #1 to dry 2% of the bagasse. Bpgasse will be mixed with gas in vertical duct and subsequently separated by cyclone. It will then be re-elevated to the main distribution carrier. 1 1 VICTORIA DE JULIO 5 Boilers 4,0 kg/, 2 kg/cm2, 4 , VEB Dampferzeugerbau, Berlin, including 2 Drums Superheater, 2 Stages 5 Solid Fuel Feed Chutes 4 Fuel Oil Injection Nozzles 1 Dump Grate 1 Forced Draft Fan, 8 kW Motor 1 Secondary Air Fan, 2.7 kW Motor 1 Induced Draft Fan, 2 kW Motor, 6.3 kV 1 Air Pre-Heater 1 Steel Stack 1 Set of Automatic Controls 3 Auxiliary Air Compressor, 3 m3/ 2 Phosphate Mixing Tanks, 1.4 mm, 1.2 m3 5 Phosphate Dosing Pumps, 2 1/, 4 , 0.8 kW Motor 2 Flash Tanks for Continuous Blow-Down, 1 TM/ 1 Boiler Feed Water Make-Up Treatment Supply Tank, 1,0 1 1 Flocculant Preparation and Dosing Tank, 1,0 2 Flocculant Dosing Pumps, 1 1/, 1 , Motors 1 Milk of Lime Mixing and Storage Tank, 3.2 m3, Stirrer, Motor 2 MOL Circulation Pumps, 1 m3/, 1 , 3 kW Motors 1 MOL Dosing Tank, 1,0 1 2 MOL Dosing Pumps, 1 1/, 1 , Motors 1 Clarifier,

Reclaiming Bagasse from Enclosed and Open Storage, 2.1 5 , 0.8 /sec, 8 /, Chain Drive, Gearbox, 4 kW Motor 1 Drag-Type Bagasse Return Conveyor (#, 2.1 3 , 0.8 /sec, 8 /, Inclined, Chain Drive, Gearbox, 3 kW Motor Drag-Type Bagasse Transfer Conveyor (#, 2.1 9 , 0.6 /sec, 8 /, Chain Drive, Gearbox, 5.5 kW Motor There is under construction drier that will use flue gases from boiler #1 to dry 2% of the bagasse. Bpgasse will be mixed with gas in vertical duct and subsequently separated by cyclone. It will then be re-elevated to the main distribution carrier. 1 1 VICTORIA DE JULIO 5 Boilers 4,0 kg/, 2 kg/cm2, 4 , VEB Dampferzeugerbau, Berlin, including 2 Drums Superheater, 2 Stages 5 Solid Fuel Feed Chutes 4 Fuel Oil Injection Nozzles 1 Dump Grate 1 Forced Draft Fan, 8 kW Motor 1 Secondary Air Fan, 2.7 kW Motor 1 Induced Draft Fan, 2 kW Motor, 6.3 kV 1 Air Pre-Heater 1 Steel Stack 1 Set of Automatic Controls 3 Auxiliary Air Compressor, 3 m3/ 2 Phosphate Mixing Tanks, 1.4 mm, 1.2 m3 5 Phosphate Dosing Pumps, 2 1/, 4 , 0.8 kW Motor 2 Flash Tanks for Continuous Blow-Down, 1 TM/ 1 Boiler Feed Water Make-Up Treatment Supply Tank, 1,0 1 1 Flocculant Preparation and Dosing Tank, 1,0 2 Flocculant Dosing Pumps, 1 1/, 1 , Motors 1 Milk of Lime Mixing and Storage Tank, 3.2 m3, Stirrer, Motor 2 MOL Circulation Pumps, 1 m3/, 1 , 3 kW Motors 1 MOL Dosing Tank, 1,0 1 2 MOL Dosing Pumps, 1 1/, 1 , Motors 1 Clarifier,| Model Type | Helical speed reduction gearbox H4 |

|---|---|

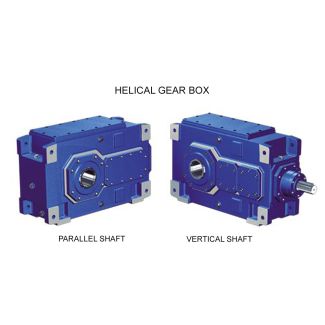

| Gear Type | Helical Gear |

| Weight (kg) | 6700.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 640000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender de Mexico, S.A. de C.V. |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-DV-23-D eration Air humidity Operation in large halls Tem Helical speed reduction gearbox H4 |