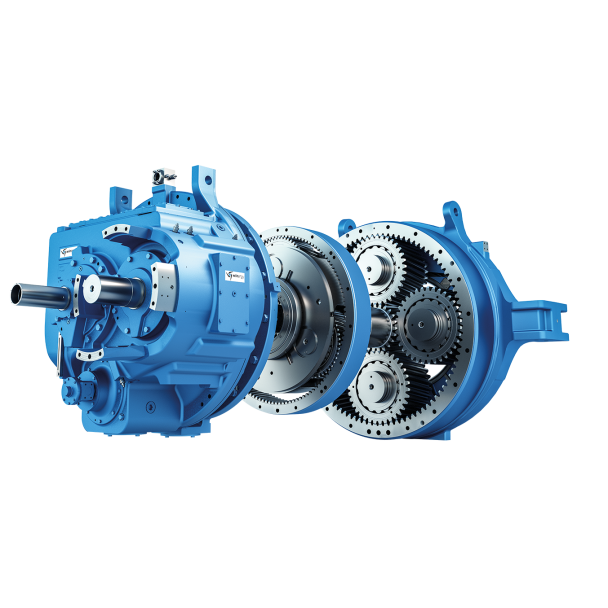

H4-DV-24B iption of the system e g industry con veyor s Helical gear units H4

In stock

SKU

H4-DV-24B

$173,571.43

Flender/Flender Gear Units/Helical gear units H4

ing each rotation. The teeth generate splashing effect. Some of the oil is also spattered onto the interior wall of the housing. An oil mist forms, which aids in the cooling, lubrication and heat dissipation during operation. This type of

the housing. An oil mist forms, which aids in the cooling, lubrication and heat dissipation during operation. This type of  lubrication is typically found in gear units that are in horizontal mounting position. If the temperatures are below the values

lubrication is typically found in gear units that are in horizontal mounting position. If the temperatures are below the values  as listed in the table on page 2/7 , heating is required. In case of dip lubrication, the oil temperature

as listed in the table on page 2/7 , heating is required. In case of dip lubrication, the oil temperature  must not drop below the pour point of the selected oil. 2. In case of dip lubrication, all parts to be lubricated are submersed in oil. The gear units are often inserted vertically and designed with an "oil expansion tank", to provide the space required by the change in volume of the oil due to the usual warming. This also applies to the "high speed shaft over low speed shaft" mounting position. If the temperatures are below the values as listed in the table on page 2/7 , heating is required. In case of dip lubrication, the oil temperature must not drop below the pour point of the selected oil. Forced lubrication/oil circulation lubrication In an oil circulation lubrication system, all of the bearing points and meshing that are not located in oil are supplied with oil via pump (motor pump, cooling/lubricating system pump or an attached flange-mounted pump). For selection criteria, see Chapter 6 . When an oil circulation lubricati on system is used, the operating viscosity must not exceed 1 cSt. At temperature limits below those listed in the table on page 2/7 , dip lubrication or gear unit heating system must be provided. Combination of lubrication types In practice, dip and forced lubrication are often provided together. Transport/storage/non-operational setup under the following conditions (in months): Packaging/storage envi- ronment of the unit Air with little or no salt content and low or average humidity and low or average air pollution acc. to EN ISO 9 (Annex ) Corr

must not drop below the pour point of the selected oil. 2. In case of dip lubrication, all parts to be lubricated are submersed in oil. The gear units are often inserted vertically and designed with an "oil expansion tank", to provide the space required by the change in volume of the oil due to the usual warming. This also applies to the "high speed shaft over low speed shaft" mounting position. If the temperatures are below the values as listed in the table on page 2/7 , heating is required. In case of dip lubrication, the oil temperature must not drop below the pour point of the selected oil. Forced lubrication/oil circulation lubrication In an oil circulation lubrication system, all of the bearing points and meshing that are not located in oil are supplied with oil via pump (motor pump, cooling/lubricating system pump or an attached flange-mounted pump). For selection criteria, see Chapter 6 . When an oil circulation lubricati on system is used, the operating viscosity must not exceed 1 cSt. At temperature limits below those listed in the table on page 2/7 , dip lubrication or gear unit heating system must be provided. Combination of lubrication types In practice, dip and forced lubrication are often provided together. Transport/storage/non-operational setup under the following conditions (in months): Packaging/storage envi- ronment of the unit Air with little or no salt content and low or average humidity and low or average air pollution acc. to EN ISO 9 (Annex ) Corr| Model Type | Helical gear units H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 725000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Singapore Pte. Ltd. |

| Country of Manufacture | Djibouti |

| Data Sheet & Drawings | H4-DV-24B iption of the system e g industry con veyor s Helical gear units H4 |