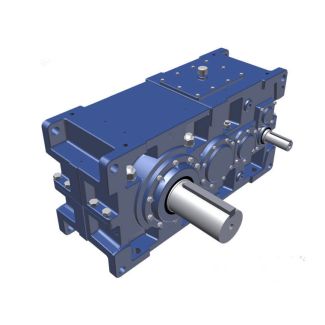

H4-DV-26-D g flange short spacer Housing flange long mou Helical gear reducer H4

In stock

SKU

H4-DV-26-D

$210,000.00

Flender/Flender Gear Units/Helical gear reducer H4

ing operated with the control system developed for adjusting the extractor capacity. 3% reduction in diffuse emissions was determined in comparison with the reference area. The project goals were thus achieved. Dilution of the exhaust gases was successfully prevent- ed.

comparison with the reference area. The project goals were thus achieved. Dilution of the exhaust gases was successfully prevent- ed.  This improvement was achieved by temporarily making throttled extractor capacity available to certain electrolysis cells undergoing an emission-intensive phase due

This improvement was achieved by temporarily making throttled extractor capacity available to certain electrolysis cells undergoing an emission-intensive phase due  to the respective proc- ess. This was made possible by the process control equipment exploiting de ree of freedom in

to the respective proc- ess. This was made possible by the process control equipment exploiting de ree of freedom in  order to suppress feedback effects on the cells on collecting manifold fofowing multiple increases in extractor capacity. Finally, comparison ofthisworkwiththepresentationsfromtheliteratureis intendedtoshow the problems of the feasible improvement as regards diffuse emission. In the graph below, the HAW characteristic curve ( is compared with other, similar cell coverings ()and () of differ- ent types. The straight line () is an ex erimentally determined limiting value which was meas- ured with hermetic sealing of the si& covering; this was presented in the same work. The HAW straight line ( presents the general degree of collection for closed cell in normal conditions, determined at 7 m3/min. The comparison shows that the slope of the functions on1 corresponds over small range; coverings ,, and ,, display pronounced de ression of tKe degree of collection after just slight reduction in the quantity extracted; thesequnctions suggest that an even lowervalue can be expected for the normal quantity of 7 m3/min. extracted at HAW, .. the HAW electrolysis cells already had comparatively good coverings at the start of this project; design measures for reducing diffuse emissions were already extensively utilised. 1 ~ ~ -___ - - -. Fig 1 Comparison of the degrees of collection 1 Duration: 0 0 - 3 0 8 0 ZH8 Subject: Environmentally friendly process for the manufacture of vanadium oxides from va

order to suppress feedback effects on the cells on collecting manifold fofowing multiple increases in extractor capacity. Finally, comparison ofthisworkwiththepresentationsfromtheliteratureis intendedtoshow the problems of the feasible improvement as regards diffuse emission. In the graph below, the HAW characteristic curve ( is compared with other, similar cell coverings ()and () of differ- ent types. The straight line () is an ex erimentally determined limiting value which was meas- ured with hermetic sealing of the si& covering; this was presented in the same work. The HAW straight line ( presents the general degree of collection for closed cell in normal conditions, determined at 7 m3/min. The comparison shows that the slope of the functions on1 corresponds over small range; coverings ,, and ,, display pronounced de ression of tKe degree of collection after just slight reduction in the quantity extracted; thesequnctions suggest that an even lowervalue can be expected for the normal quantity of 7 m3/min. extracted at HAW, .. the HAW electrolysis cells already had comparatively good coverings at the start of this project; design measures for reducing diffuse emissions were already extensively utilised. 1 ~ ~ -___ - - -. Fig 1 Comparison of the degrees of collection 1 Duration: 0 0 - 3 0 8 0 ZH8 Subject: Environmentally friendly process for the manufacture of vanadium oxides from va| Model Type | Helical gear reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 1030000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | Finland |

| Data Sheet & Drawings | H4-DV-26-D g flange short spacer Housing flange long mou Helical gear reducer H4 |