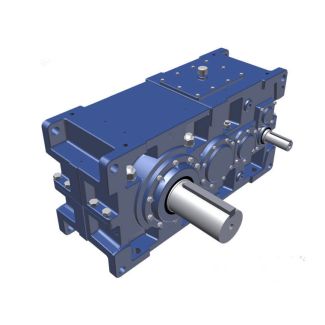

H4-DV-27-A nting flange long spacerOn housing side With gea Helical speed reducer H4

In stock

SKU

H4-DV-27-A

$254,571.43

Flender/Flender Gear Units/Helical speed reducer H4

ing particle in the -direction; Syf/H1v2 gln cos (gt/ ) ( 2. The displacement ( Syr) for rising particle in the -direction: Syr/H1/H1v2 gln sin (gt/ ) ( 3. The displacement ( Sx) nt -direction, Sx/H1vat/H1v2 glnc (/H1gt/ )( where,

the -direction: Syr/H1/H1v2 gln sin (gt/ ) ( 3. The displacement ( Sx) nt -direction, Sx/H1vat/H1v2 glnc (/H1gt/ )( where,  vt/H1suspension velocity or terminal velocity of particle /H1time elapsed /H1gravitational acceleration /H1integration constant. Harvesting and Threshing 1 Fig. 2 Trajectory

vt/H1suspension velocity or terminal velocity of particle /H1time elapsed /H1gravitational acceleration /H1integration constant. Harvesting and Threshing 1 Fig. 2 Trajectory  of grain and straw in vertical airstream. (From Ref. 6.) Gorial and OCallaghan ( used the aerodynamic and physical properties

of grain and straw in vertical airstream. (From Ref. 6.) Gorial and OCallaghan ( used the aerodynamic and physical properties  of grain and straw to calculate the net force acting on particle and obtained their trajectories in vertical airstream (Fig. . It was stated that for the downward injection, the particlescontinue on downward path, and the heavier grain particles fall nearer the wall than thelighter straw particles, which will move over 1 from the point of injection before theyare entrained in the airstream and carried upward. For an upward injection of grain andstraw, on the other hand, the straw always moves upward, requiring less width of columnto initiate the separation. The trajectories in vertical airstream of mixture of wheat particles, typical of the range observed in threshed sample, are shown in Fig. 2 for horizontal injection. On comparative basis, it is apparent from the foregoing gures that the upward injection of grain and straw mixture in vertical airstream is best, followed by horizon-tal and downward injections, for effective separation and minimum grain loss. However, Fig. 2 Trajectory of threshed mixture in vertical airstream: Injection velocity of particle, 0.5 /; air velocity 6 /; direction of injection was horizontal. (From Ref. 6.) 1 Datta Table 8 Aerodynamic and Physical Properties of Grains Shape factorTerminal Geom. Eqiv. Drag Mass velocity dia. dia. coeff. Zm Zp Grain (mg) (/) (mm) (mm) ( ) ReSphericity measured predicted Adzuki 1.6 1.6 5.4 0.5 4 0.7 0.4 0.3 Barley 3.6 7.5 4.0 3.7 0.9 1 0.4 0.2 0.1 Beans 4.0 1

of grain and straw to calculate the net force acting on particle and obtained their trajectories in vertical airstream (Fig. . It was stated that for the downward injection, the particlescontinue on downward path, and the heavier grain particles fall nearer the wall than thelighter straw particles, which will move over 1 from the point of injection before theyare entrained in the airstream and carried upward. For an upward injection of grain andstraw, on the other hand, the straw always moves upward, requiring less width of columnto initiate the separation. The trajectories in vertical airstream of mixture of wheat particles, typical of the range observed in threshed sample, are shown in Fig. 2 for horizontal injection. On comparative basis, it is apparent from the foregoing gures that the upward injection of grain and straw mixture in vertical airstream is best, followed by horizon-tal and downward injections, for effective separation and minimum grain loss. However, Fig. 2 Trajectory of threshed mixture in vertical airstream: Injection velocity of particle, 0.5 /; air velocity 6 /; direction of injection was horizontal. (From Ref. 6.) 1 Datta Table 8 Aerodynamic and Physical Properties of Grains Shape factorTerminal Geom. Eqiv. Drag Mass velocity dia. dia. coeff. Zm Zp Grain (mg) (/) (mm) (mm) ( ) ReSphericity measured predicted Adzuki 1.6 1.6 5.4 0.5 4 0.7 0.4 0.3 Barley 3.6 7.5 4.0 3.7 0.9 1 0.4 0.2 0.1 Beans 4.0 1| Model Type | Helical speed reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 11880.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | WALTHER FLENDER GMBH |

| Country of Manufacture | France |

| Data Sheet & Drawings | H4-DV-27-A nting flange long spacerOn housing side With gea Helical speed reducer H4 |