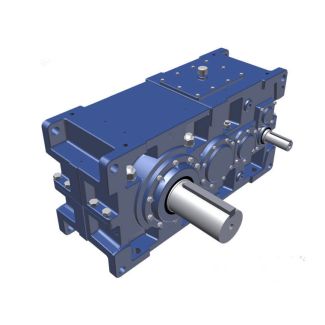

H4-DV-27-D the low speed shaftsSolid shaft with parallel key Helical gear units H4

In stock

SKU

H4-DV-27-D

$254,571.43

Flender/Flender Gear Units/Helical gear units H4

ing several weeks of this application the level can be brought down to about 1 ppm for regular application. 3.2.8 Optimum Tempering Conditions Optimum tempering in terms of moisture and time is dependent on prevailing circum- stances and conditions, including

Optimum Tempering Conditions Optimum tempering in terms of moisture and time is dependent on prevailing circum- stances and conditions, including  the ambient temperature and humidity at the location.Therefore, it is difcult to suggest an optimum milling moisture and tempering time

the ambient temperature and humidity at the location.Therefore, it is difcult to suggest an optimum milling moisture and tempering time  that will satisfy the specic requirements of all situations. Table 5 provides general guide of how different the milling moistures

that will satisfy the specic requirements of all situations. Table 5 provides general guide of how different the milling moistures  and tempering times can be for CWRS class ofwheat in different countries. The tempering conditions are altered, depending on wheat hardness as well as on the end-use quality requirements of the our. Table 6 provides range of the wheat- 2 Sarkar Table 5 Optimum Tempering Conditions for CWRS Class Wheat Factors North America South Korea Switzerland Mexico Milling moisture (%) 1.5.5 1.5.5 1.0.5 1.5.0 Tempering time () 8 4 3 5 tempering requirements for hard, soft, and durum wheats as applied by our mills in Canada. When comparing the tempering requirements of the hard and soft wheat from Table 6, it is quite clear that the milling moisture as well as tempering time requirement for soft wheat are less than those for hard wheat owing to the differences in kernel hardness. Therefore, when milling blend of hard and soft wheat, they are cleaned and temperedseparately and then blended. Hardness alone, however, does not determine the ultimatetempering requirements, as can be seen from Table 6 when comparing the temperingrequirements of hard and durum wheat. Although durum wheat is the harder of the two,its tempering time requirement is shorter than for hard wheat. The reason is that the end- use quality requirements are quite different. Hard wheat is milled to produce white and ne powdery material as nished product, whereas durum wheat is milled to produce abright golden yellow granular material. Therefore even though it is harder than hard wheat,its tem

and tempering times can be for CWRS class ofwheat in different countries. The tempering conditions are altered, depending on wheat hardness as well as on the end-use quality requirements of the our. Table 6 provides range of the wheat- 2 Sarkar Table 5 Optimum Tempering Conditions for CWRS Class Wheat Factors North America South Korea Switzerland Mexico Milling moisture (%) 1.5.5 1.5.5 1.0.5 1.5.0 Tempering time () 8 4 3 5 tempering requirements for hard, soft, and durum wheats as applied by our mills in Canada. When comparing the tempering requirements of the hard and soft wheat from Table 6, it is quite clear that the milling moisture as well as tempering time requirement for soft wheat are less than those for hard wheat owing to the differences in kernel hardness. Therefore, when milling blend of hard and soft wheat, they are cleaned and temperedseparately and then blended. Hardness alone, however, does not determine the ultimatetempering requirements, as can be seen from Table 6 when comparing the temperingrequirements of hard and durum wheat. Although durum wheat is the harder of the two,its tempering time requirement is shorter than for hard wheat. The reason is that the end- use quality requirements are quite different. Hard wheat is milled to produce white and ne powdery material as nished product, whereas durum wheat is milled to produce abright golden yellow granular material. Therefore even though it is harder than hard wheat,its tem| Model Type | Helical gear units H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 11880.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 1230000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-DV-27-D the low speed shaftsSolid shaft with parallel key Helical gear units H4 |