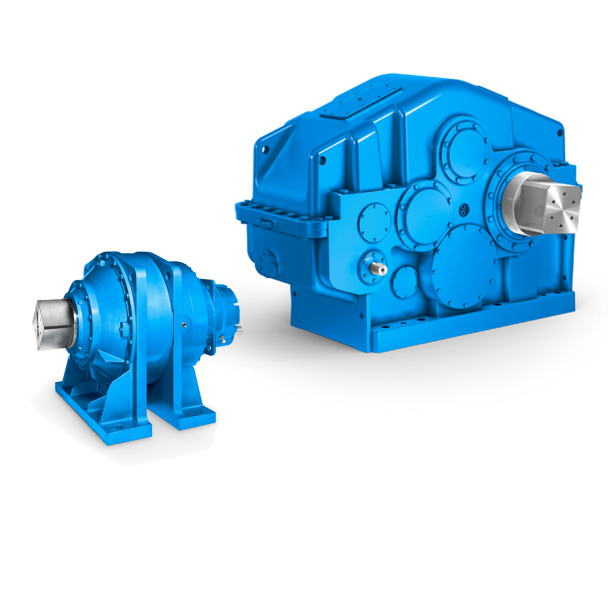

Flender/Flender Gear Units/Helical speed reducer H3

content, or more appropri-ately the water activity, dockage content, and degree of insect and mite infestation. Theoptimum temperatures for the growth of Penicillium spp. range between 2 and 2C; forA. restrictus andA. glaucus ,3 0C; and for . avus 4C.

growth of Penicillium spp. range between 2 and 2C; forA. restrictus andA. glaucus ,3 0C; and for . avus 4C.  Most fungi require at least an wof 0.7 to grow, and they cause spoilage at or above an awof 0.8.

Most fungi require at least an wof 0.7 to grow, and they cause spoilage at or above an awof 0.8.  Composition of the intergranular air also inuences the growth of fungi. Oxygen at less than 1% levelretards the development (.

Composition of the intergranular air also inuences the growth of fungi. Oxygen at less than 1% levelretards the development (.  Stored grain insects, particularly the secondary pests andscavengers, moving inside the grain mass disseminate fungi and facilitate inoculation. Thegrains damaged by insects help the mold invade. Grain germ is the most susceptible part for the storage fungi for invasion and subse- quent development. The germ is killed and discoloration takes place following infection,and this lowers the grade of the grain as sick or damaged, thereby, reducing themarket value. The baking quality of wheat is also affected (. Besides dry matter loss,biochemical changes such as hydrolysis of glycerides of grain lipids giving rise to in-creased levels of free fatty acids have been observed (. Furthermore, the commoditybecomes rancid with musty odor caused by volatiles developed from the oxidation of free unsaturated fatty acids. Any malodorous or discolored grain is not acceptable to food processors, as it will have repercussions in the end-use products. Active respiration offungi and other microorganisms leads to heating of the grain (. When the temperaturerises to 5 , grains become caked and black, with burned appearance (Fig. . At this stage, the grains become unacceptable and unt for human as well as animal consumption. The early stages of infection by storage fungi can be detected by enumeration tech- niques after plating surface-disinfected kernels on suitable agar medium (direct-plating method) or by dilution-plating method. Qualitative tests, based on the estimation ofconstituents of fungi (chitin

Stored grain insects, particularly the secondary pests andscavengers, moving inside the grain mass disseminate fungi and facilitate inoculation. Thegrains damaged by insects help the mold invade. Grain germ is the most susceptible part for the storage fungi for invasion and subse- quent development. The germ is killed and discoloration takes place following infection,and this lowers the grade of the grain as sick or damaged, thereby, reducing themarket value. The baking quality of wheat is also affected (. Besides dry matter loss,biochemical changes such as hydrolysis of glycerides of grain lipids giving rise to in-creased levels of free fatty acids have been observed (. Furthermore, the commoditybecomes rancid with musty odor caused by volatiles developed from the oxidation of free unsaturated fatty acids. Any malodorous or discolored grain is not acceptable to food processors, as it will have repercussions in the end-use products. Active respiration offungi and other microorganisms leads to heating of the grain (. When the temperaturerises to 5 , grains become caked and black, with burned appearance (Fig. . At this stage, the grains become unacceptable and unt for human as well as animal consumption. The early stages of infection by storage fungi can be detected by enumeration tech- niques after plating surface-disinfected kernels on suitable agar medium (direct-plating method) or by dilution-plating method. Qualitative tests, based on the estimation ofconstituents of fungi (chitin| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 25500.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | WALTHER FLENDER GMBH |

| Country of Manufacture | Morocco |

| Data Sheet & Drawings | H3-VH28A flender bh Helical speed reducer H3 |