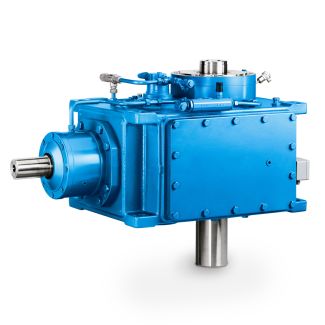

Flender/Flender Gear Units/Helical gear unit H3

complicated and it is very little treated in the literature, but usually as economic category. 3. Adoption which is carried out by gear units designe rs in order to select optimal design solution. This adoption procedure is also po orly

out by gear units designe rs in order to select optimal design solution. This adoption procedure is also po orly  treated in literature, so that this paper would try to treat that problem more det ailed on this place. 3.

treated in literature, so that this paper would try to treat that problem more det ailed on this place. 3.  GEAR UNITS ADOPTION USING MANUFACTURERS CATALOG UES Gear units manufacturers, through their catalogues, provide detailed instructions for adoption and mounting

GEAR UNITS ADOPTION USING MANUFACTURERS CATALOG UES Gear units manufacturers, through their catalogues, provide detailed instructions for adoption and mounting  of their pro ducts, and the customers and purchasers should comply with them when adopting ge ar unit. Mainly, in the frame ANNALS OF THE FACULTY OF ENGINEERING HUNEDOARA JO URNAL OF ENGINEERING. TOME (. Fascicole 3 2 of required speed ratio it is necessary to adopt th at gear unit which satisfy the condition: TN fB , ( ie. the output torque load capacity of gear unit ( TN) should be greater than product of service factor ( fB) and operational torque ( ), as it is shown on Fig. 1. In the frame of necessary motor power and required revolution number of motor gear units, the adopted gear unit has to sati sfy the condition that value of permissible service factor is greater than necessar value, ie.: fBD fB ( After that, it is required that existing overhang oads at the gear unit shaft have to be smaller than permissible values of overhang oads: FRexis. FRperm. ( FAexis. FAperm. ( and also, transmitted power ( ) have to be smaller than, so called, thermal capac ity of gear unit ( PQ), ie. the following condition has to be satisfied: PQ ( Manufacturers of gear units always consider this co ndition when they compile their catalogues, and if the condition is not satis fied for particular gear unit, that gear unit can not be shown in the catalogue. Some gear units manufacturers indicate the maximum temperature up to which their gear units can be exposed: perm. ( or

of their pro ducts, and the customers and purchasers should comply with them when adopting ge ar unit. Mainly, in the frame ANNALS OF THE FACULTY OF ENGINEERING HUNEDOARA JO URNAL OF ENGINEERING. TOME (. Fascicole 3 2 of required speed ratio it is necessary to adopt th at gear unit which satisfy the condition: TN fB , ( ie. the output torque load capacity of gear unit ( TN) should be greater than product of service factor ( fB) and operational torque ( ), as it is shown on Fig. 1. In the frame of necessary motor power and required revolution number of motor gear units, the adopted gear unit has to sati sfy the condition that value of permissible service factor is greater than necessar value, ie.: fBD fB ( After that, it is required that existing overhang oads at the gear unit shaft have to be smaller than permissible values of overhang oads: FRexis. FRperm. ( FAexis. FAperm. ( and also, transmitted power ( ) have to be smaller than, so called, thermal capac ity of gear unit ( PQ), ie. the following condition has to be satisfied: PQ ( Manufacturers of gear units always consider this co ndition when they compile their catalogues, and if the condition is not satis fied for particular gear unit, that gear unit can not be shown in the catalogue. Some gear units manufacturers indicate the maximum temperature up to which their gear units can be exposed: perm. ( or| Model Type | Helical gear unit H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 345000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Siemens |

| Country of Manufacture | Indonesia |

| Data Sheet & Drawings | H3-VH20A flender n eupex Helical gear unit H3 |