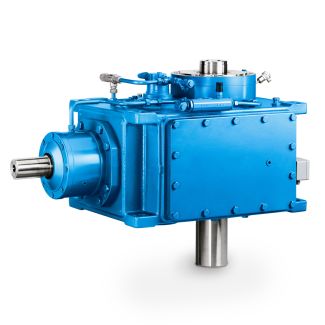

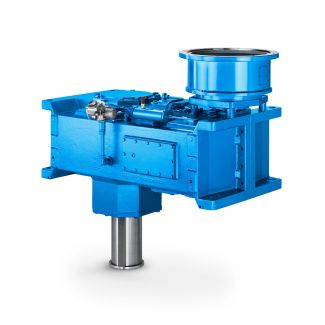

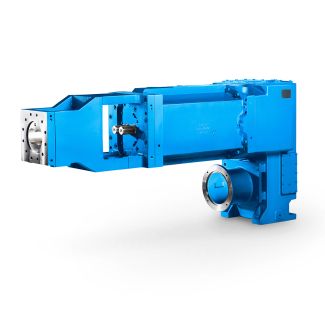

H3-VH-21-A flender extruder gearbox Helical speed reducer H3

In stock

SKU

H3-VH-21-A

$195,000.00

Flender/Flender Gear Units/Helical speed reducer H3

comprehen-sive product portfolio. The advantage is that all components are optimally attuned to one another, and the best possible combination can be configured for almost any application. The next level is the vertical. Here, Siemens employs its Totally Integrated Automation

can be configured for almost any application. The next level is the vertical. Here, Siemens employs its Totally Integrated Automation  (TIA) concept. The added value includes efficient configuration, faster integration and commissioning, greater flexibility in production, high- er availability, and

(TIA) concept. The added value includes efficient configuration, faster integration and commissioning, greater flexibility in production, high- er availability, and  the potential to effi-ciently implement measures to save energy. There are great advantages to having IT integrated throughout plant: For

the potential to effi-ciently implement measures to save energy. There are great advantages to having IT integrated throughout plant: For  one, says Lbben, plant management has access to key data and can keep an eye on everything. What makes it even more interesting is that service expert can be sitting somewhere in Europe and monitoring plant in South America. For our custom- ers with global operations this is great advantage, particularly because it is possible to consolidate operations and also easier to share best practices throughout an organization.Engineered to perfection Siemens is the only supplier that delivers everything along the entire drive train, says Lbben. In effect, what customers are getting is solutions- based approach that combines prod-ucts, application engineering and ser - vices into one. This means that there is nothing piecemeal about solutions from Siemens, he says. The problem with piecemeal projects is that they fail or exceed the budget because, during the course of the proj-ect, it becomes obvious that the inter - faces dont fit, that specifications dont match, or that the individual compo- nents cant be delivered to the construc- tion site on time. Considering these potential problems, the advantages of single-source provider with one line of responsibility become obvious: From gears and motors to couplings and drives, everything works together right from the start. The project can also be perfectly coordinated. The single-line approach also pre- vents costly over-engineering. M

one, says Lbben, plant management has access to key data and can keep an eye on everything. What makes it even more interesting is that service expert can be sitting somewhere in Europe and monitoring plant in South America. For our custom- ers with global operations this is great advantage, particularly because it is possible to consolidate operations and also easier to share best practices throughout an organization.Engineered to perfection Siemens is the only supplier that delivers everything along the entire drive train, says Lbben. In effect, what customers are getting is solutions- based approach that combines prod-ucts, application engineering and ser - vices into one. This means that there is nothing piecemeal about solutions from Siemens, he says. The problem with piecemeal projects is that they fail or exceed the budget because, during the course of the proj-ect, it becomes obvious that the inter - faces dont fit, that specifications dont match, or that the individual compo- nents cant be delivered to the construc- tion site on time. Considering these potential problems, the advantages of single-source provider with one line of responsibility become obvious: From gears and motors to couplings and drives, everything works together right from the start. The project can also be perfectly coordinated. The single-line approach also pre- vents costly over-engineering. M| Model Type | Helical speed reducer H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9100.000000 |

| Ratio Range | 1 : 22.4…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 420000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER GUSS GMBH |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H3-VH-21-A flender extruder gearbox Helical speed reducer H3 |