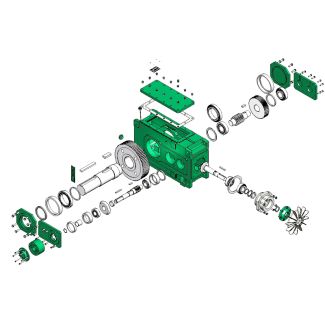

H3-SV-22-D motoreducteur flender Helical gear Reduction Boxes H3

In stock

SKU

H3-SV-22-D

$210,000.00

Flender/Flender Gear Units/Helical gear Reduction Boxes H3

chemical process, namely, the Othmer (or Azeotropic) distillation process, issuperior to the preceding methods as far as recovery of acetic acid, methanol, and other wood chemicals is concerned (. Fig. 8 Half-orange kiln. 8 Chakraverty 6 CHEMICAL AND BIOCHEMICAL PROCESSING

acid, methanol, and other wood chemicals is concerned (. Fig. 8 Half-orange kiln. 8 Chakraverty 6 CHEMICAL AND BIOCHEMICAL PROCESSING  6.1 Amorphous Silica and Combustible GasThe rice husk is composed of approximately 3% cellulose, 1% petosan, 2% lignin, 2% ash

6.1 Amorphous Silica and Combustible GasThe rice husk is composed of approximately 3% cellulose, 1% petosan, 2% lignin, 2% ash  (mainly silica), and 2% other organics. The biogenic silica present in rice husk and rice straw is inherently amorphous. The

(mainly silica), and 2% other organics. The biogenic silica present in rice husk and rice straw is inherently amorphous. The  carbon-free white ash (silica) obtained from rice straw and husk has opened new dimension in its utilization concept. This silica hasbeen found to be an attractive source for manufacturing pure silicon and other chemicalproducts (. The straws (1 cm in length) or husks are thoroughly cleaned with water and sun dried. The dried materials are leached with mineral acids at 7 for 1 and washed with distilled water several times to remove the acids and then dried in the sun to lower the moisture content (..) to 6% to 7% wet basis (..). The temperature of vertical electric furnace is raised to the desired constant temper- ature and then straw or husk is fed into the furnace to expose it to the stable furnacetemperature with natural draft. Combustion continues till the entire mass is convertedinto white ash. The structure of silica in the white ash has been examined by the -ray diffraction technique to determine the formation of any crystallinity during combustion of straw or husk at high temperatures. When the bed thickness of straw and husk increases in the furnace, the ame temper- ature and the duration of ame also increase. If the furnace temperature increases, theame temperature also increases for both straw and husk. For the production of low- calorie combustible gas along with the amorphous silica, both raw and acid-treated straw and husk containing 6% to 7% (..) moisture should be subjected to furnace tempera- ture of 4 (. At furnace tem

carbon-free white ash (silica) obtained from rice straw and husk has opened new dimension in its utilization concept. This silica hasbeen found to be an attractive source for manufacturing pure silicon and other chemicalproducts (. The straws (1 cm in length) or husks are thoroughly cleaned with water and sun dried. The dried materials are leached with mineral acids at 7 for 1 and washed with distilled water several times to remove the acids and then dried in the sun to lower the moisture content (..) to 6% to 7% wet basis (..). The temperature of vertical electric furnace is raised to the desired constant temper- ature and then straw or husk is fed into the furnace to expose it to the stable furnacetemperature with natural draft. Combustion continues till the entire mass is convertedinto white ash. The structure of silica in the white ash has been examined by the -ray diffraction technique to determine the formation of any crystallinity during combustion of straw or husk at high temperatures. When the bed thickness of straw and husk increases in the furnace, the ame temper- ature and the duration of ame also increase. If the furnace temperature increases, theame temperature also increases for both straw and husk. For the production of low- calorie combustible gas along with the amorphous silica, both raw and acid-treated straw and husk containing 6% to 7% (..) moisture should be subjected to furnace tempera- ture of 4 (. At furnace tem| Model Type | Helical gear Reduction Boxes H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 25…100 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 470000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | Tunisia |

| Data Sheet & Drawings | H3-SV-22-D motoreducteur flender Helical gear Reduction Boxes H3 |