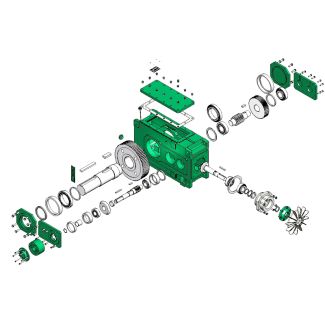

H3-SV23-B flender technical handbook Helical gearbox H3

In stock

SKU

H3-SV23-B

$254,571.43

Flender/Flender Gear Units/Helical gearbox H3

Chiles Antapaccay mine (page . On our home turf in Germany, we reveal how we have helped Reichwalde mine optimize technological process chains. The trip contin- ues to the Philippines where we show how we have helped Holcim improve its

technological process chains. The trip contin- ues to the Philippines where we show how we have helped Holcim improve its  cement operations for example through intensive staff training for the Siemens automation system CEMAT based on SIMATIC PCS7 (page .

cement operations for example through intensive staff training for the Siemens automation system CEMAT based on SIMATIC PCS7 (page .  We also look at how Siemens is helping Indonesia and Malaysia meet their growing demand for cement. Finally, we take

We also look at how Siemens is helping Indonesia and Malaysia meet their growing demand for cement. Finally, we take  an excursion to the steel sector for an article on new pelletizing tech-nology (page . We hope you enjoy reading this magazine and we look forward to greeting you at this years bauma in Munich, Germany (page .Dear Reader, MineralsFocus 2/2 | Contents With cash at premium, CAPEX and OPEX have become even more important for mining operations 1Siemens helps get CO 2 emissions from cement plants as low as possible1 Minerals automation standard for mining improves productivity, plant availability and efficiency4 Siemens has been making mark on Turkmenistans cement industry 4Contents 5Contents | MineralsFocus 2/2 Cover Story 1 No stop in sight Siemens has been involved in the mining industry since 1, initially in Germany and today at mines all over the world. And in these 9 years, the company has kept pace with changes on all levels. 1 partner for today and tomorrow The two big topics in the cement industry today are energy use and CO 2 emissions. Siemens offers solutions to optimize energy use today, and the company has its sights on solutions for tomorrow, as Dieter Schletterer, Vice Presi-dent Cement Minerals, explains.Mining 2 Serving the worlds biggest producersSiemens Chile and Peru 2 Belts rolling at AntapaccayGearless drives 2 Smoother, faster and more efficient Modern drive technology for belt conveyors 3 Unmanned operation boosts reliabilityStockpile management 3 decisive stepSiemens introduces the Minerals Automation Standard Cement 4 Strengt

an excursion to the steel sector for an article on new pelletizing tech-nology (page . We hope you enjoy reading this magazine and we look forward to greeting you at this years bauma in Munich, Germany (page .Dear Reader, MineralsFocus 2/2 | Contents With cash at premium, CAPEX and OPEX have become even more important for mining operations 1Siemens helps get CO 2 emissions from cement plants as low as possible1 Minerals automation standard for mining improves productivity, plant availability and efficiency4 Siemens has been making mark on Turkmenistans cement industry 4Contents 5Contents | MineralsFocus 2/2 Cover Story 1 No stop in sight Siemens has been involved in the mining industry since 1, initially in Germany and today at mines all over the world. And in these 9 years, the company has kept pace with changes on all levels. 1 partner for today and tomorrow The two big topics in the cement industry today are energy use and CO 2 emissions. Siemens offers solutions to optimize energy use today, and the company has its sights on solutions for tomorrow, as Dieter Schletterer, Vice Presi-dent Cement Minerals, explains.Mining 2 Serving the worlds biggest producersSiemens Chile and Peru 2 Belts rolling at AntapaccayGearless drives 2 Smoother, faster and more efficient Modern drive technology for belt conveyors 3 Unmanned operation boosts reliabilityStockpile management 3 decisive stepSiemens introduces the Minerals Automation Standard Cement 4 Strengt| Model Type | Helical gearbox H3 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 11880.000000 |

| Ratio Range | 1 : 22.4…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 640000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender France S.A.R.L. |

| Country of Manufacture | Turkmenistan |

| Data Sheet & Drawings | H3-SV23-B flender technical handbook Helical gearbox H3 |