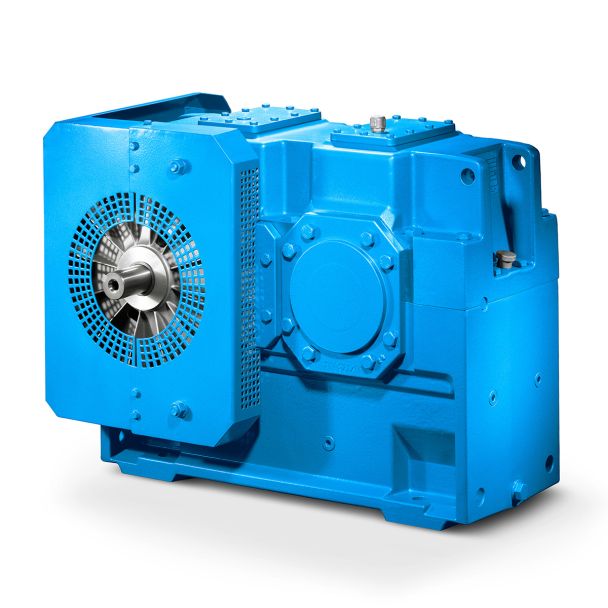

H2-FV-20B flender türkiye distribütörü Helical gear units H2

In stock

SKU

H2-FV-20B

$160,714.29

Flender/Flender Gear Units/Helical gear units H2

ble safety gloves and suitable safety glasses . Only spare parts made by the manufacturer Flender must be used. Any enquiries should be addressed to: Flender GmbH Schlavenhorst 1 Bocholt Tel.: +4 (0)2 / 9-0 Technical offer and Cost (0)2

enquiries should be addressed to: Flender GmbH Schlavenhorst 1 Bocholt Tel.: +4 (0)2 / 9-0 Technical offer and Cost (0)2  / 9-2 1UZWN overrunning clutches with KSUN clutch shift 3 en Assembly and operating instructions 1/2. Fitting The clutch parts

/ 9-2 1UZWN overrunning clutches with KSUN clutch shift 3 en Assembly and operating instructions 1/2. Fitting The clutch parts  are supplied in finished condition in accordance with the order. set screw to standard "DIN 9" with cup point must

are supplied in finished condition in accordance with the order. set screw to standard "DIN 9" with cup point must  be used when securing the clutch parts. If the clutch part fitted on the shaft does not lie up against the shaft shoulder, we recommend using grooved spacer rings. The overrunning clutches are balanced to the customer' specifications. 3.1 Notes to the fit pairs of the bore and shaft Check the fits of the bores and the shafts. Table 5: Fit recommendation for bores with parallelkey connection DescriptionPush fit Press fit Interference fit not suitable for reversing operationsuitable for reversing operation Shaft tolerance j6 h6 h6 k6 m6 n6 h6 Bore tolerance H7 J7 K7 H7 H7 H7 M7 The fit assignment m6 / H7 is particularly suitable for many applications. Failure to observe these instructions may result in breakage of the overrunning clutch. Danger to life from flying fragments. 3.2 Fitting the UZWN overrunning clutch 3.2.1 Fitting the UZWN overrunning clutch, sizes 3 / 4 / 5 / 6 The subassembly clutch part 1 (1; 3; 5; 6; 7; 8; 1; 1; 5; 5; is delivered in preassembled condition. Unscrew the set screw. Clean the bores and shaft ends. The bellows ( must not come into contact with solvents and cleaning agents. Insert parallel keys in the shaft ends. Undo the screw connection (5; on the subassembly clutch part 1 (1; 3; 5; 6; 7; 8; 1; 1; 5; 5; and demount the bellows (. Undo cheese head screws ( and demount dust protection (. Push bellows ( onto shaft. Coat the bores of the coupling parts (1; and the shafts with MoS 2 mounting paste (.. Microgleit LP . Mount clutch part 1 and clutch part 2, heat

be used when securing the clutch parts. If the clutch part fitted on the shaft does not lie up against the shaft shoulder, we recommend using grooved spacer rings. The overrunning clutches are balanced to the customer' specifications. 3.1 Notes to the fit pairs of the bore and shaft Check the fits of the bores and the shafts. Table 5: Fit recommendation for bores with parallelkey connection DescriptionPush fit Press fit Interference fit not suitable for reversing operationsuitable for reversing operation Shaft tolerance j6 h6 h6 k6 m6 n6 h6 Bore tolerance H7 J7 K7 H7 H7 H7 M7 The fit assignment m6 / H7 is particularly suitable for many applications. Failure to observe these instructions may result in breakage of the overrunning clutch. Danger to life from flying fragments. 3.2 Fitting the UZWN overrunning clutch 3.2.1 Fitting the UZWN overrunning clutch, sizes 3 / 4 / 5 / 6 The subassembly clutch part 1 (1; 3; 5; 6; 7; 8; 1; 1; 5; 5; is delivered in preassembled condition. Unscrew the set screw. Clean the bores and shaft ends. The bellows ( must not come into contact with solvents and cleaning agents. Insert parallel keys in the shaft ends. Undo the screw connection (5; on the subassembly clutch part 1 (1; 3; 5; 6; 7; 8; 1; 1; 5; 5; and demount the bellows (. Undo cheese head screws ( and demount dust protection (. Push bellows ( onto shaft. Coat the bores of the coupling parts (1; and the shafts with MoS 2 mounting paste (.. Microgleit LP . Mount clutch part 1 and clutch part 2, heat| Model Type | Helical gear units H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 7500.000000 |

| Ratio Range | 1 : 7.1…22.8 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 335000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Oman |

| Data Sheet & Drawings | H2-FV-20B flender türkiye distribütörü Helical gear units H2 |