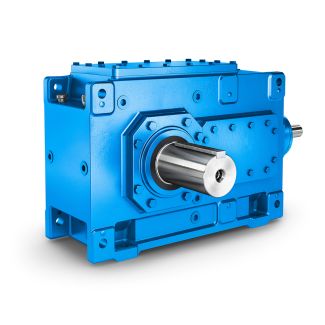

Bevel-helical speed reducer B4 water flow regulator vibration damper etc For B4KV-12-C

In stock

SKU

B4KV-12-C

$37,500.00

Flender/Flender Gear Units/Bevel-helical speed reducer B4

ve circular arc tooth trace with constant tooth depth. The cutter resembles that of the Zyklo-Palloid method, being divided in two parts, but only with inner and outer blades; there are no roughing ormiddle blades. The two-part cutter is necessary

two parts, but only with inner and outer blades; there are no roughing ormiddle blades. The two-part cutter is necessary  to produce an exact tapered spaceand slot width. Both the pinion and wheel are generated. Lengthwise crowning iscreated by xed

to produce an exact tapered spaceand slot width. Both the pinion and wheel are generated. Lengthwise crowning iscreated by xed  specied difference in cutter radii. The method is characterizedby high degree of standardization, allowing small number of tools to cover

specied difference in cutter radii. The method is characterizedby high degree of standardization, allowing small number of tools to cover  alarge range of gear production. However, standardization also means that length-wise crowning results from the choice of cutter size and cannot be modied freely. Machines are no longer produced for this method. 5-cut The term 5-cut method derives from the steps in which the gears are manufactured. The wheel is machined in two cuts (roughing and nishing),.. both tooth anks are cut simultaneously; the pinion is machined in three cuts, .. roughing of both tooth anks, nishing of the convex tooth ank and nishing of the concave tooth ank. It is single indexing or face milling method with acircular arc tooth trace and with tapered teeth. The generating motion is generallyrelated to the root cone rather than to the pitch cone, as would be kinematicallycorrect. As feature of this method, the wheel is nished in two-ank cut and thepinion in single ank cuts. The machine and tool settings for one ank of the pinionare independent of those for the other. One resulting advantage lies in the indepen-dent geometries of the concave and convex pinion tooth anks, since any change in machine kinematics for subsequent ank modications on one side has no effect on the other side. Lengthwise crowning is usually obtained by differences in cutterradii, while prole crowning is obtained by modifying the machine kinematics. Themethod is used for both generated and non-generated bevel gears. It is still used on alarge scale in the aircraft industry, but has largely been replaced by the

alarge range of gear production. However, standardization also means that length-wise crowning results from the choice of cutter size and cannot be modied freely. Machines are no longer produced for this method. 5-cut The term 5-cut method derives from the steps in which the gears are manufactured. The wheel is machined in two cuts (roughing and nishing),.. both tooth anks are cut simultaneously; the pinion is machined in three cuts, .. roughing of both tooth anks, nishing of the convex tooth ank and nishing of the concave tooth ank. It is single indexing or face milling method with acircular arc tooth trace and with tapered teeth. The generating motion is generallyrelated to the root cone rather than to the pitch cone, as would be kinematicallycorrect. As feature of this method, the wheel is nished in two-ank cut and thepinion in single ank cuts. The machine and tool settings for one ank of the pinionare independent of those for the other. One resulting advantage lies in the indepen-dent geometries of the concave and convex pinion tooth anks, since any change in machine kinematics for subsequent ank modications on one side has no effect on the other side. Lengthwise crowning is usually obtained by differences in cutterradii, while prole crowning is obtained by modifying the machine kinematics. Themethod is used for both generated and non-generated bevel gears. It is still used on alarge scale in the aircraft industry, but has largely been replaced by the| Model Type | Bevel-helical speed reducer B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1750.000000 |

| Ratio Range | 1 : 100…400 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 78000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens Industriegetriebe GmbH, Penig |

| Country of Manufacture | Vanuatu |

| Data Sheet & Drawings | Bevel-helical speed reducer B4 water flow regulator vibration damper etc For B4KV-12-C |