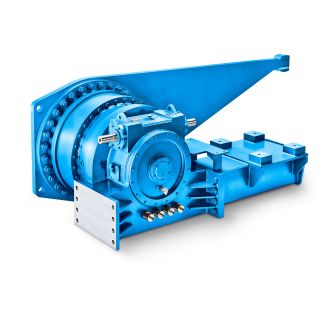

B3FH-11-C B V Dip lubrication LP Air inta Bevel-helical speed reducer B3

In stock

SKU

B3FH-11-C

$40,285.71

Flender/Flender Gear Units/Bevel-helical speed reducer B3

s. Bevel gear measurement plays an important part inmachine capability testing, which represents decisive criterion for productionmachines of all kinds. The second task of bevel gear metrology is to determine the geometry of the tooth anks as actually manufactured in

The second task of bevel gear metrology is to determine the geometry of the tooth anks as actually manufactured in  order to guarantee that the previouslycalculated and developed form of the tooth anks, including all modications, hasbeen achieved in the

order to guarantee that the previouslycalculated and developed form of the tooth anks, including all modications, hasbeen achieved in the  production process. If tolerances are shown to have beenexceeded, the setting parameters of the production machines must be corrected. Inthe

production process. If tolerances are shown to have beenexceeded, the setting parameters of the production machines must be corrected. Inthe  past, such corrections were generally made on the basis of contact pattern testsand then set manually on the machines. Since the 1s, however, production hasbeen transformed by the quality assurance closed loop (see Sect. 7.1.5 ), in which corrective machine setting values are calculated automatically from the results of measurement and are then transferred to the machine. In the spiral bevel gearmanufacturing sector, this has made bevel gear production much more exibleand progressive than that of other gear types. Springer-Verlag Berlin Heidelberg 2 . Klingelnberg (ed.), Bevel Gear , DOI 1.1/9-3-6-4-0_7 7.1.2 Pitch Measurement In principle, circular pitch measurement on bevel gears follows exactly the same procedures as on cylindrical gears. measurement of this kind could be made usingsimple pitch testing devices without any detailed knowledge of the design. How-ever, it has become customary to combine pitch measurement to the study of toothank topography using 3D gear measuring machine. The pitch is measured in thetransverse section, generally in the middle of the tooth ank. Depending on thechosen standard, the assessment is converted to the point at which the relevant tolerances relate. For example, DIN 3 [ DIN3 ] is used for the pitch quality of bevel gears. The tables contained in DIN 3 refer to the corresponding cylindrical gearstandard [ DIN3 ], but allow bevel gears bonus accuracy grade. This means that bevel gear is

past, such corrections were generally made on the basis of contact pattern testsand then set manually on the machines. Since the 1s, however, production hasbeen transformed by the quality assurance closed loop (see Sect. 7.1.5 ), in which corrective machine setting values are calculated automatically from the results of measurement and are then transferred to the machine. In the spiral bevel gearmanufacturing sector, this has made bevel gear production much more exibleand progressive than that of other gear types. Springer-Verlag Berlin Heidelberg 2 . Klingelnberg (ed.), Bevel Gear , DOI 1.1/9-3-6-4-0_7 7.1.2 Pitch Measurement In principle, circular pitch measurement on bevel gears follows exactly the same procedures as on cylindrical gears. measurement of this kind could be made usingsimple pitch testing devices without any detailed knowledge of the design. How-ever, it has become customary to combine pitch measurement to the study of toothank topography using 3D gear measuring machine. The pitch is measured in thetransverse section, generally in the middle of the tooth ank. Depending on thechosen standard, the assessment is converted to the point at which the relevant tolerances relate. For example, DIN 3 [ DIN3 ] is used for the pitch quality of bevel gears. The tables contained in DIN 3 refer to the corresponding cylindrical gearstandard [ DIN3 ], but allow bevel gears bonus accuracy grade. This means that bevel gear is| Model Type | Bevel-helical speed reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1880.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 63500 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B3FH-11-C B V Dip lubrication LP Air inta Bevel-helical speed reducer B3 |