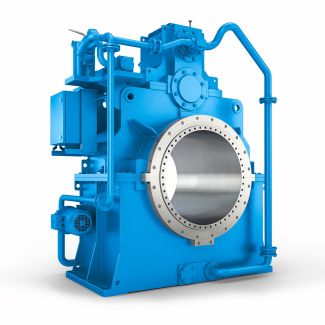

B3FH-12-C For details on the shafts see Chapter For forc Bevel-helical gearboxes B3

In stock

SKU

B3FH-12-C

$40,714.29

Flender/Flender Gear Units/Bevel-helical gearboxes B3

S/CROMPTON/ BHARTIA INDUST RIES LT / RAS CONT ROL / BIECCO LAWREE LTD 3 HRC USE GE INDUSTRIAL / & / SIEMENS/ STANDARD/ ABB/ CONTROL & SWITCHGEAR OMPANY TD/ STANDARD ELECTRICALS LTD. 3 HOOT ERS TULLU/ NATIONAL 3 AIR CONDITIONER

/ SIEMENS/ STANDARD/ ABB/ CONTROL & SWITCHGEAR OMPANY TD/ STANDARD ELECTRICALS LTD. 3 HOOT ERS TULLU/ NATIONAL 3 AIR CONDITIONER  ACCA IRE/ BLU STAR / VOLTAS/ GODREJ/ CARRIE /LG 3 TRANSW ITCH UNIT TRANSGIETZ 4 UNITIZED SUBSTATION TRANSGIETZ 4 HV

ACCA IRE/ BLU STAR / VOLTAS/ GODREJ/ CARRIE /LG 3 TRANSW ITCH UNIT TRANSGIETZ 4 UNITIZED SUBSTATION TRANSGIETZ 4 HV  FIELD SW ITCH (. 6 kV) TRANSGIETZ 4 DSC, CADA,CCT ,RTU for sub-station autom ation and electrical SCADA HONE YWE

FIELD SW ITCH (. 6 kV) TRANSGIETZ 4 DSC, CADA,CCT ,RTU for sub-station autom ation and electrical SCADA HONE YWE  LL 1 Background The Rolls Royce Distributed Generation Systems (RRDGS), located in Winsford, Cheshire UK, is leading manufacturer in the design, development and support of small, high-performance power generation and power management, distribution and conversion systems. RRDGS systems are designed for harsh environments or remote locations requiring highly-mobile, high-specification products for military applications. The Project RRDSG required new test facility to enable validation testing of new spare parts for their (Napier) Deltic 9 diesel engines. RRDSGs original facility had fire and the majority of their spares parts were lost. So new parts were re-drawn and then tested for performance before fitting to the engines that are in service. Implementation The partnership of Taylor Dynamometer and Dynamometer Services Group (DSG) collaborated on the project. DSG built the test stand while Taylor provided the equipment for the test facility based around Taylors DX3 water brake (hydraulic) engine dynamometer.Business Challenge and SolutionBecause of the two-stroke design of the engine and the reliance of engine control without the presence of governor or limiter, the performance of the dynamometer and control system was paramount to ensure steady state load control with minimal overshoot. Also, the addition of Siemens Flender Speed-Increasing Gearbox was used to bring the shaft speed into the speed-range of the sensibly-sized DX3 engine dynamometer. Results Taylor Dynamo

LL 1 Background The Rolls Royce Distributed Generation Systems (RRDGS), located in Winsford, Cheshire UK, is leading manufacturer in the design, development and support of small, high-performance power generation and power management, distribution and conversion systems. RRDGS systems are designed for harsh environments or remote locations requiring highly-mobile, high-specification products for military applications. The Project RRDSG required new test facility to enable validation testing of new spare parts for their (Napier) Deltic 9 diesel engines. RRDSGs original facility had fire and the majority of their spares parts were lost. So new parts were re-drawn and then tested for performance before fitting to the engines that are in service. Implementation The partnership of Taylor Dynamometer and Dynamometer Services Group (DSG) collaborated on the project. DSG built the test stand while Taylor provided the equipment for the test facility based around Taylors DX3 water brake (hydraulic) engine dynamometer.Business Challenge and SolutionBecause of the two-stroke design of the engine and the reliance of engine control without the presence of governor or limiter, the performance of the dynamometer and control system was paramount to ensure steady state load control with minimal overshoot. Also, the addition of Siemens Flender Speed-Increasing Gearbox was used to bring the shaft speed into the speed-range of the sensibly-sized DX3 engine dynamometer. Results Taylor Dynamo| Model Type | Bevel-helical gearboxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Industriegetriebe GmbH |

| Country of Manufacture | Grenada |

| Data Sheet & Drawings | B3FH-12-C For details on the shafts see Chapter For forc Bevel-helical gearboxes B3 |