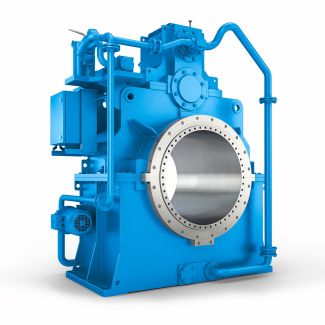

B3-FH-12-D ed lubrication approximately h can be assumed as Bevel-helical gear boxes B3

In stock

SKU

B3-FH-12-D

$40,714.29

Flender/Flender Gear Units/Bevel-helical gear boxes B3

s6.3 Heat Treatment 2 Quenching in vaporizing media like oils or aqueous polymer solutions implies considerable distortion potential. All liquid quenching media have boiling point signicantly below the work piece temperature at the beginning of the quenching process. The quenching

quenching media have boiling point signicantly below the work piece temperature at the beginning of the quenching process. The quenching  medium does not wet the surface of the work piece, but rather surrounds it with layer of steam of low

medium does not wet the surface of the work piece, but rather surrounds it with layer of steam of low  thermal conductivity which keeps the medium away from the surface. This so-called Leidenfrost effect locally pro- duces very different cooling

thermal conductivity which keeps the medium away from the surface. This so-called Leidenfrost effect locally pro- duces very different cooling  rates, when departure from lm boiling occurs. Fig- ure6.2 represents different phases in the quenching process. At the start of quenching, the entire surface of the work piece is insulated from the quenching medium by the vapor lm. As the temperature falls, the boiling phase forms. In this phase both the quenching medium itself and small steam bubbles cool the work piece further. Once the work piece temperature falls below the boiling point, the convection phase begins, further cooling the work piece through the ow of the quenching medium over its surface. As the re-wetting front progresses over the surface, the point of maximum volume change likewise migrates as result of thermal contraction. The boundary may be located at several points simultaneously. The three stages of heat transfer, with their different cooling rates, consequently generate an extremely inhomoge- neous stress state in the bevel gear. Moreover, the teeth disturb an even circulation around the surface and steam bubbles may cling in the tooth slots and delay the course of martensite formation. remedy here may come from agitation systems in the quenching tank which help the steam skin to break down without forcing the pace of heat transfer excessively through too strong ow. Fig. 6.2 Steam shell, boiling and convection phase of the quenching process2 6 Manufacturing Process These problems do not arise with non-vaporizing media such as gases and molten salts or metals which have

rates, when departure from lm boiling occurs. Fig- ure6.2 represents different phases in the quenching process. At the start of quenching, the entire surface of the work piece is insulated from the quenching medium by the vapor lm. As the temperature falls, the boiling phase forms. In this phase both the quenching medium itself and small steam bubbles cool the work piece further. Once the work piece temperature falls below the boiling point, the convection phase begins, further cooling the work piece through the ow of the quenching medium over its surface. As the re-wetting front progresses over the surface, the point of maximum volume change likewise migrates as result of thermal contraction. The boundary may be located at several points simultaneously. The three stages of heat transfer, with their different cooling rates, consequently generate an extremely inhomoge- neous stress state in the bevel gear. Moreover, the teeth disturb an even circulation around the surface and steam bubbles may cling in the tooth slots and delay the course of martensite formation. remedy here may come from agitation systems in the quenching tank which help the steam skin to break down without forcing the pace of heat transfer excessively through too strong ow. Fig. 6.2 Steam shell, boiling and convection phase of the quenching process2 6 Manufacturing Process These problems do not arise with non-vaporizing media such as gases and molten salts or metals which have| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1900.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 77200 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | B3-FH-12-D ed lubrication approximately h can be assumed as Bevel-helical gear boxes B3 |