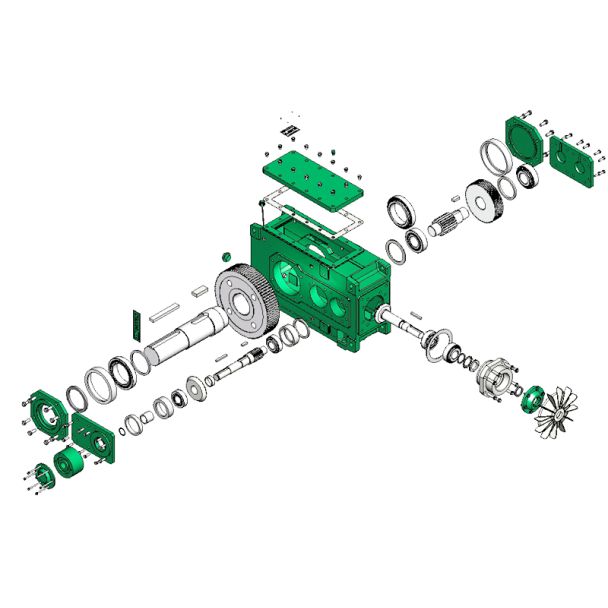

cc to orderrelated documentation Without oil fil B3-HH-10B Bevel-helical gear boxes B3

In stock

SKU

B3-HH-10B

$19,928.57

Flender/Flender Gear Units/Bevel-helical gear boxes B3

prevent blower tripping, the Operator sets minimum valve opening positions that ensure minimum airflow. Also cell airflow measurements are used to override DO controlled valve open position to ensure diffuser minimum and maximum airflows are maintained 1 The modified aeration

to override DO controlled valve open position to ensure diffuser minimum and maximum airflows are maintained 1 The modified aeration  control system setup can be viewed to be similar to feedback cascade ammonia DO control system without automatic measurement of

control system setup can be viewed to be similar to feedback cascade ammonia DO control system without automatic measurement of  the effluent ammonia 4-6 The basic aeration control philosophy is therefore fixe DO setpoint. Because of the better efficiency of

the effluent ammonia 4-6 The basic aeration control philosophy is therefore fixe DO setpoint. Because of the better efficiency of  the control algorithm used for Module 1, the chief operator mentioned that they are planning to modify the design control philosophy to the one applied for Module 1. Figure 4-4: Module 2 Turbo Blowers (Photo Courtesy efTEC) 4.2.6 Tertiary Treatment In order to ensure final effluent compliance with Ortho limits at all times, standby ferric chloride dosing facilities were installed to supplement biological removal when required. Dosing can be either into the mixed liquor effluent channel from the biorea ctors prior to secondary clarification or effluent from the SSTs prior to the rapid sand filtration. Effluent from the SSTs for each module flows to set of rapid sand filters. After filtration effluent from the two sets of filters is collected in common su mp and then equally distributed to two chlorine contact tanks for disinfection prior to discharge to the maturation dam. Final effluent from the maturation dam overflows to the Roodeplaat dam. 4.2.7 Sludge Handling and Treatment Commissioning of the new sludge handling and treatmen facility started in January 2. The facility consists of: Two primary sludge fermenters for VFA generation . The elutriant is returned to the balancing tanks Two fermented sludge thickeners for thickening fermented primary sludge. The thickeners also receive thickened overflow from the DAF units that thi

the control algorithm used for Module 1, the chief operator mentioned that they are planning to modify the design control philosophy to the one applied for Module 1. Figure 4-4: Module 2 Turbo Blowers (Photo Courtesy efTEC) 4.2.6 Tertiary Treatment In order to ensure final effluent compliance with Ortho limits at all times, standby ferric chloride dosing facilities were installed to supplement biological removal when required. Dosing can be either into the mixed liquor effluent channel from the biorea ctors prior to secondary clarification or effluent from the SSTs prior to the rapid sand filtration. Effluent from the SSTs for each module flows to set of rapid sand filters. After filtration effluent from the two sets of filters is collected in common su mp and then equally distributed to two chlorine contact tanks for disinfection prior to discharge to the maturation dam. Final effluent from the maturation dam overflows to the Roodeplaat dam. 4.2.7 Sludge Handling and Treatment Commissioning of the new sludge handling and treatmen facility started in January 2. The facility consists of: Two primary sludge fermenters for VFA generation . The elutriant is returned to the balancing tanks Two fermented sludge thickeners for thickening fermented primary sludge. The thickeners also receive thickened overflow from the DAF units that thi| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 930.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 43800 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | cc to orderrelated documentation Without oil fil B3-HH-10B Bevel-helical gear boxes B3 |