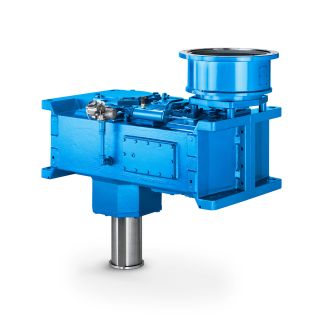

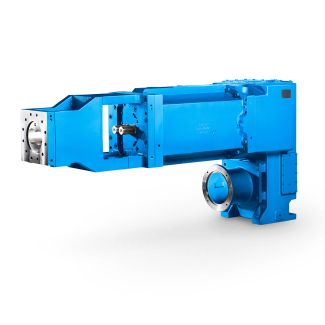

g see page Flender GmbH Flender MD Helica B3-HH11-B Bevel-helical gear Reduction Boxes B3

In stock

SKU

B3-HH11-B

$40,285.71

Flender/Flender Gear Units/Bevel-helical gear Reduction Boxes B3

prior to the actual welding of the joints. 1.9 Weather Conditions 1.9.1 The parts being welded and the welding personnel should be protected from rain and strong winds. In the absence of such protection no welding sh all be carried

should be protected from rain and strong winds. In the absence of such protection no welding sh all be carried  out. 1.9.2 During field welding using GTAW process, particular care shall be exercised to prevent any air current affecting the

out. 1.9.2 During field welding using GTAW process, particular care shall be exercised to prevent any air current affecting the  welding process. 1.1 Welding 1.1.1 Root Pass ) Root pass shall be made with electrodes/ filler wires recommended in the

welding process. 1.1 Welding 1.1.1 Root Pass ) Root pass shall be made with electrodes/ filler wires recommended in the  welding specification chart. The preferable size of the electrode is 2.5mm diameter (1 SWG) but in no case greater than 3.2mm (1 SWG). ) Uphill welding shall be adopted for welding pipes weld fix ed with its axis horizontal. Downward technique of welding shall not be used for pipes in horizontal position, unless specifically permitted by Engineer-in-charge for particular case. 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 2 of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 ) The root pass of but joints should be executed properly so as to achieve full penetration with complete fusion of the root edges. Weld projec tion inside the pipe shall not exceed .4mm wherever not specified by the applic able code. ) Any deviations desired from the recommended welding techni que and electrodes indicated in the welding specification chart should be adopted only after obtaining express approval of the Engineer-in-charge. ) Welding shall be continuous & uninterrupted during pass. ) On completion of each run, craters, welding irregularities, slag etc., shall be removed by grinding and chiselling. ) void any kind of movement of components, to prevent occurrence of weld cracks. ) Fillet welds shall be made by shielded metal arc/ GTAW welding process irrespective of the thickness and class of p

welding specification chart. The preferable size of the electrode is 2.5mm diameter (1 SWG) but in no case greater than 3.2mm (1 SWG). ) Uphill welding shall be adopted for welding pipes weld fix ed with its axis horizontal. Downward technique of welding shall not be used for pipes in horizontal position, unless specifically permitted by Engineer-in-charge for particular case. 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 2 of 6 TITLE MEC//0/2/0 REVISION : 0 PIPING FABRICATION AND ERECTION EDITION : 1 ) The root pass of but joints should be executed properly so as to achieve full penetration with complete fusion of the root edges. Weld projec tion inside the pipe shall not exceed .4mm wherever not specified by the applic able code. ) Any deviations desired from the recommended welding techni que and electrodes indicated in the welding specification chart should be adopted only after obtaining express approval of the Engineer-in-charge. ) Welding shall be continuous & uninterrupted during pass. ) On completion of each run, craters, welding irregularities, slag etc., shall be removed by grinding and chiselling. ) void any kind of movement of components, to prevent occurrence of weld cracks. ) Fillet welds shall be made by shielded metal arc/ GTAW welding process irrespective of the thickness and class of p| Model Type | Bevel-helical gear Reduction Boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1880.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 63500 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. FRIEDR. FLENDER AG |

| Country of Manufacture | Mexico |

| Data Sheet & Drawings | g see page Flender GmbH Flender MD Helica B3-HH11-B Bevel-helical gear Reduction Boxes B3 |