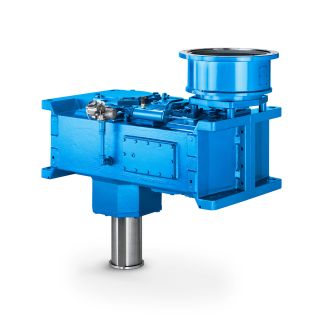

rces including those caused by weight of gear unit B3-HH-10-D Bevel-helical speed reducers B3

In stock

SKU

B3-HH-10-D

$19,928.57

Flender/Flender Gear Units/Bevel-helical speed reducers B3

priate to reach this aim. Organosolv pulping means to digest plant materials by means of or- ganic solvents or mixtures of organic solvents and water. Compared to the conventional pulping processes, .. the sulphite and the sulphate rocess the organosolv

of organic solvents and water. Compared to the conventional pulping processes, .. the sulphite and the sulphate rocess the organosolv  process allows to separate the three main components of lignocefulosics; cellulose, hemicellulose and lignin of high purity can be produced.

process allows to separate the three main components of lignocefulosics; cellulose, hemicellulose and lignin of high purity can be produced.  Because there are no sulphuric cooking ents by far lower pollution of waste water and waste air can be supposed.

Because there are no sulphuric cooking ents by far lower pollution of waste water and waste air can be supposed.  Furthermore ctemical recovery can be carried out by relatively simple redestillation of the solvents. However the attractive possibilities of organosolv pulping can only be used if the partly known technical and technological difficulties can be overcome. 2. Working Steps On the basis of process parameters developed in the pilot plant demonstration plantforthe production of 5 tpd bleached pulp was designed, constructed and erected This plant isa com- 2 . 2 plete small pulp mill in itself: with its help the pul ing process can be optimized and essential parts of thechemical recoverycan be realized witkn closed continuous process. Thedemon- stration plant represents the transition to the industrial scale application of the Organocell pro- cess. The attached flow diagram gives survey of the plant. With wood chips of spruce or pine the plant is run discontinuously(tostartwith), then continuously.Testswith hardwood are possible as well. The control devices are designed for mainly automatic operation of the continuous cooking. Controlling has been adjusted and optimized with the help of test results from the pilot plant as mell as from the first experiences with the demonstration plant. Test operation is also of great significance for personnel training. There are fifteen employees working in three shifts. The pulp has been used in field tests for the roduction of decorative paper at the Pasing facili- ties of the Technocell AG where the th

Furthermore ctemical recovery can be carried out by relatively simple redestillation of the solvents. However the attractive possibilities of organosolv pulping can only be used if the partly known technical and technological difficulties can be overcome. 2. Working Steps On the basis of process parameters developed in the pilot plant demonstration plantforthe production of 5 tpd bleached pulp was designed, constructed and erected This plant isa com- 2 . 2 plete small pulp mill in itself: with its help the pul ing process can be optimized and essential parts of thechemical recoverycan be realized witkn closed continuous process. Thedemon- stration plant represents the transition to the industrial scale application of the Organocell pro- cess. The attached flow diagram gives survey of the plant. With wood chips of spruce or pine the plant is run discontinuously(tostartwith), then continuously.Testswith hardwood are possible as well. The control devices are designed for mainly automatic operation of the continuous cooking. Controlling has been adjusted and optimized with the help of test results from the pilot plant as mell as from the first experiences with the demonstration plant. Test operation is also of great significance for personnel training. There are fifteen employees working in three shifts. The pulp has been used in field tests for the roduction of decorative paper at the Pasing facili- ties of the Technocell AG where the th| Model Type | Bevel-helical speed reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 930.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 43800 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | Malta |

| Data Sheet & Drawings | rces including those caused by weight of gear unit B3-HH-10-D Bevel-helical speed reducers B3 |