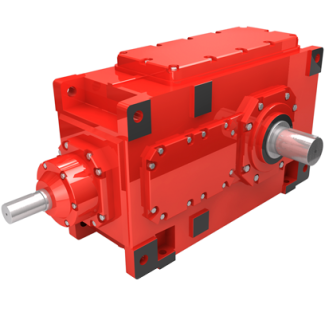

Bevel-helical gear Reduction Box B2 peed shaft LSS of a gear unit is calculated accor B2HH-13-C

In stock

SKU

B2HH-13-C

$83,035.71

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B2

mounted with brushes are used for the purpose. The powder particles are removedby the rubbing action. Speed and sizes of these types of polisher are similar to those of the cylindrical dehusking roller (see Table . Another type of machinery

these types of polisher are similar to those of the cylindrical dehusking roller (see Table . Another type of machinery  provided for this purpose is set of screw conveyors arranged in battery for repeated rubbings. The ights and shaft are

provided for this purpose is set of screw conveyors arranged in battery for repeated rubbings. The ights and shaft are  covered with nylonrope or velvet cloth. The speed of each screw conveyor varies. The repeated rubbing addsto the luster of

covered with nylonrope or velvet cloth. The speed of each screw conveyor varies. The repeated rubbing addsto the luster of  the dal, which makes it more attractive. These polishers are commonlyknown as nylon polisher or velvet polisher, depending on the material used, and are avail-able in set of 2, 3, 4, or 5 screw conveyors. 3.5.1.2 Oil and Water Polish The screw conveyor similar to one supplied for oil and water mixing is provided for oil and water polish. The speed, size, and capacity, are similar to those of the oil and water mixing machine. 4 Sokhansanj and Patil Table 7 Emery Sizes (No.) for Roller Machine Operation Crop Pitting Splitting Polishing Arhar (pigeon pea) 1 2 Mung (green gram) 2 3 3Urd (black gram) 2 3 3 Chickpea 2 Source : Ref. 7. 3.5.2 Splitting of Pulses Splitting of dehusked pulses and pulse seeds is one of the major operations in the dal mill. It is aimed at the production of perfect splits, with edges and without breakage.Different types of equipment are employed for the purpose: roller machine, under runner disk sheller, attrition mill (Chakki), elevator and hard surface, and impact sheller. 3.5.2.1 Roller Machine The machine similar to one used for dehusking is used for splitting of different pulses. course emery coating is required for the splitter roller (Table . The rollers are usedfor splitting green gram, pigeon pea, lentil, and others. Roller machines are based on the principle of abrasion. Revolutions and diameter of roller (peripheral speed), roughness of surface, length of roller (hold-up time), abrasion force, abrasion pressure, and clearancebetween the roller and the

the dal, which makes it more attractive. These polishers are commonlyknown as nylon polisher or velvet polisher, depending on the material used, and are avail-able in set of 2, 3, 4, or 5 screw conveyors. 3.5.1.2 Oil and Water Polish The screw conveyor similar to one supplied for oil and water mixing is provided for oil and water polish. The speed, size, and capacity, are similar to those of the oil and water mixing machine. 4 Sokhansanj and Patil Table 7 Emery Sizes (No.) for Roller Machine Operation Crop Pitting Splitting Polishing Arhar (pigeon pea) 1 2 Mung (green gram) 2 3 3Urd (black gram) 2 3 3 Chickpea 2 Source : Ref. 7. 3.5.2 Splitting of Pulses Splitting of dehusked pulses and pulse seeds is one of the major operations in the dal mill. It is aimed at the production of perfect splits, with edges and without breakage.Different types of equipment are employed for the purpose: roller machine, under runner disk sheller, attrition mill (Chakki), elevator and hard surface, and impact sheller. 3.5.2.1 Roller Machine The machine similar to one used for dehusking is used for splitting of different pulses. course emery coating is required for the splitter roller (Table . The rollers are usedfor splitting green gram, pigeon pea, lentil, and others. Roller machines are based on the principle of abrasion. Revolutions and diameter of roller (peripheral speed), roughness of surface, length of roller (hold-up time), abrasion force, abrasion pressure, and clearancebetween the roller and the| Model Type | Bevel-helical gear Reduction Box B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3875.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 81100 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Oy |

| Country of Manufacture | Turkmenistan |

| Data Sheet & Drawings | Bevel-helical gear Reduction Box B2 peed shaft LSS of a gear unit is calculated accor B2HH-13-C |