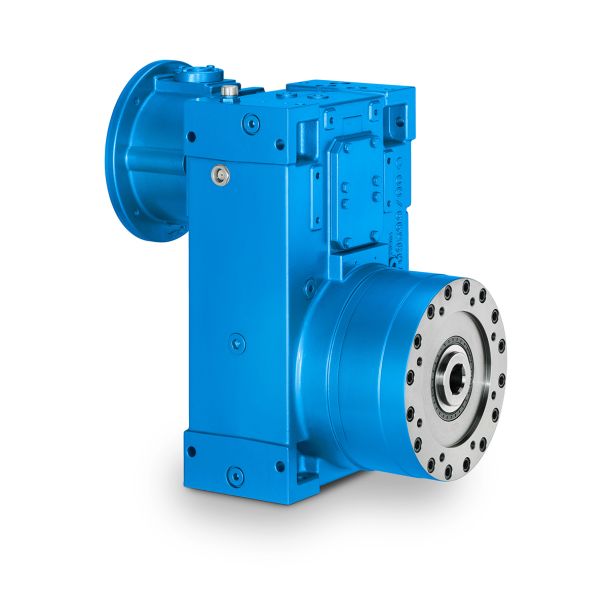

ar unit sizes to Selection and ordering data con B2-KV13-B Bevel-helical speed reducers B2

In stock

SKU

B2-KV13-B

$254,571.43

Flender/Flender Gear Units/Bevel-helical speed reducers B2

ning installation from Messrs. Durr, iving special consideration to environmental relevance (air, water). The applicability of the la8oratory results to cleaning operations in the actual production process could be tested in this way. Parallel to this project, the cleaning effect

cleaning operations in the actual production process could be tested in this way. Parallel to this project, the cleaning effect  of HHC-free, non- ueous media was tested on laboratory scale in comparison experiments and their applicgility to practical technologies was

of HHC-free, non- ueous media was tested on laboratory scale in comparison experiments and their applicgility to practical technologies was  then determined in an explosion-protected KLN installation. 3. Results The goal of these Sub-Projects, carried out within the framework of

then determined in an explosion-protected KLN installation. 3. Results The goal of these Sub-Projects, carried out within the framework of  the project ,,Reduction of halogenated hydrocarbon emissions, was to enable the reduction of halogenated hydrocar- bon emissions resulting from cleaning processes in the electrical industry by developing and testing process and media which preserve the environment. In summary, the following state- ment can be made following the conclusion of the project: Based on market roducts, number of aqueous cleaners were developed which meet the high demands of tEe electrical industry as regards material compatibility and cleanin effect In this context, the optimisation work was based on the results of basic physical anc?chemical experimental methods. The following products were developed: VR 5 Alkaline dip cleaner VR 5-1 Low-foam, alkaline dip cleaner VR 5-1 Low-foam, alkaline dip cleaner VR 5-1 Alkaline spra cleaner VR6-3 Neutral dip cLaner 0 P3-neutrapon 5 mod. Neutral spray cleaner When HHC degreasing is converted to cleaning with aqueous media, shift in environmental problems from the air to the water must be avoided. The aim should be the Ion est possible service life of the cleanin and rinsing baths. Therefore, concepts weredrawn up8r extending the service life through % use of membrane processes, particularly ultrafiltration. Following the cleaning phase, the surfaces often have to be protected from corrosion. Oils, which often still use HHCs as solvent, are primarily used to attain long

the project ,,Reduction of halogenated hydrocarbon emissions, was to enable the reduction of halogenated hydrocar- bon emissions resulting from cleaning processes in the electrical industry by developing and testing process and media which preserve the environment. In summary, the following state- ment can be made following the conclusion of the project: Based on market roducts, number of aqueous cleaners were developed which meet the high demands of tEe electrical industry as regards material compatibility and cleanin effect In this context, the optimisation work was based on the results of basic physical anc?chemical experimental methods. The following products were developed: VR 5 Alkaline dip cleaner VR 5-1 Low-foam, alkaline dip cleaner VR 5-1 Low-foam, alkaline dip cleaner VR 5-1 Alkaline spra cleaner VR6-3 Neutral dip cLaner 0 P3-neutrapon 5 mod. Neutral spray cleaner When HHC degreasing is converted to cleaning with aqueous media, shift in environmental problems from the air to the water must be avoided. The aim should be the Ion est possible service life of the cleanin and rinsing baths. Therefore, concepts weredrawn up8r extending the service life through % use of membrane processes, particularly ultrafiltration. Following the cleaning phase, the surfaces often have to be protected from corrosion. Oils, which often still use HHCs as solvent, are primarily used to attain long| Model Type | Bevel-helical speed reducers B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 11880.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 81100 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender..Ltd China(Tianjin) |

| Country of Manufacture | Poland |

| Data Sheet & Drawings | ar unit sizes to Selection and ordering data con B2-KV13-B Bevel-helical speed reducers B2 |