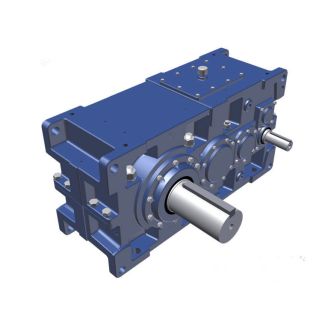

Bevel-helical speed reduction gearbox B2 s continued The mass moment of inertia J in kgm r B2-HH-9-D

In stock

SKU

B2-HH-9-D

$35,892.86

Flender/Flender Gear Units/Bevel-helical speed reduction gearbox B2

moisture contentwere soaked in water at 2 for 4 min. Under these conditions, moisturized rice of 1% moisture content developed the least number of cracks. During tests, distinctivesnap-crackle-pop noise can be heard coming from low-moisture rice, indicating theseverity of the

the least number of cracks. During tests, distinctivesnap-crackle-pop noise can be heard coming from low-moisture rice, indicating theseverity of the  stresses being built up within the rice grains as moisture begins to enterthe kernel. Fig. 1 Rice cracking during soaking

stresses being built up within the rice grains as moisture begins to enterthe kernel. Fig. 1 Rice cracking during soaking  (in water at 2 for 4 min) moisturized to () 1.0, () 1.0, and () 1.0% moisture contents. Rice moisturized

(in water at 2 for 4 min) moisturized to () 1.0, () 1.0, and () 1.0% moisture contents. Rice moisturized  to 1.0% moisture content shows theleast number of cracks compared with rice of lower moisture. Rice Milling and Processing 3 This cracking phenomenon during soaking is of great importance, particularly in those countries where cultural practices entail prolonged washing and soaking of the ricebefore cooking. Still, the same phenomenon also takes place during the initial phase ofcooking rice, so this is universal problem. The potential benet of moisture addition to rice is one of enhanced quality. Not only are the weight and volume of the rice increased, but the quality is also improved in terms of yielding better-tasting, better-cooking rice. It is expected that future millingtechnology will be expanded to include moisture conditioning as standard processingstep. 2.7 Separation of Broken Grains from Whole Grains In most rice mills broken grains are removed from whole grains through process of length-grading actions. Later these broken grains can either be marketed separately orblended with whole grains to produce specic products. 2.7.1 Sifters The separation of milled rice into whole and broken grains typically requires high- capacity, moderately efcient length grader. The sifter typically separates the milled rice into three streams: whole grains, mixture of whole and broken grains, and small broken grains with some larger brokengrains. The dimensions of the opening in the screen determine the efciency of sifting. The capacity of the machine is largely determined

to 1.0% moisture content shows theleast number of cracks compared with rice of lower moisture. Rice Milling and Processing 3 This cracking phenomenon during soaking is of great importance, particularly in those countries where cultural practices entail prolonged washing and soaking of the ricebefore cooking. Still, the same phenomenon also takes place during the initial phase ofcooking rice, so this is universal problem. The potential benet of moisture addition to rice is one of enhanced quality. Not only are the weight and volume of the rice increased, but the quality is also improved in terms of yielding better-tasting, better-cooking rice. It is expected that future millingtechnology will be expanded to include moisture conditioning as standard processingstep. 2.7 Separation of Broken Grains from Whole Grains In most rice mills broken grains are removed from whole grains through process of length-grading actions. Later these broken grains can either be marketed separately orblended with whole grains to produce specic products. 2.7.1 Sifters The separation of milled rice into whole and broken grains typically requires high- capacity, moderately efcient length grader. The sifter typically separates the milled rice into three streams: whole grains, mixture of whole and broken grains, and small broken grains with some larger brokengrains. The dimensions of the opening in the screen determine the efciency of sifting. The capacity of the machine is largely determined| Model Type | Bevel-helical speed reduction gearbox B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1675.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 29900 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | flanders electric peru s a c |

| Country of Manufacture | Slovakia |

| Data Sheet & Drawings | Bevel-helical speed reduction gearbox B2 s continued The mass moment of inertia J in kgm r B2-HH-9-D |