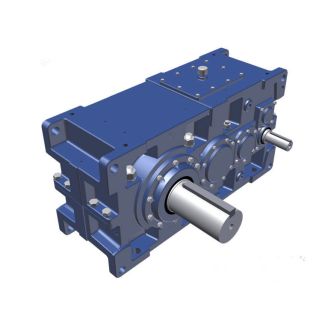

Bevel-helical gear Reduction Box B2 elative to the low speed shaft LSS of a gear unit B2-HH-10-A

In stock

SKU

B2-HH-10-A

$49,178.57

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B2

moisture migration in bins exposedto signicant changes in ambient temperature. Aeration is also used to cool grain afterdrying, to keep damp grain cool until it can be dried, to remove storage odors, or to Commercial Grain Dryers 1 distribute fumigants

damp grain cool until it can be dried, to remove storage odors, or to Commercial Grain Dryers 1 distribute fumigants  in the grain mass. This operation is usually carried out in storage bin that is equipped with fan, duct system,

in the grain mass. This operation is usually carried out in storage bin that is equipped with fan, duct system,  and perforated oor, along with exhaust ventsto provide escape for moist air. Whether or not the ventilating air is blown

and perforated oor, along with exhaust ventsto provide escape for moist air. Whether or not the ventilating air is blown  upward orsucked down through the grain is largely matter of choice. Upward ventilation is morecommonly used, although there are advantages and disadvantages to each of these meth- ods. An important advantage of using upward ventilation is that it allows storage tempera- tures to be measured easily because the warmest air is always at the top of the pile. Therecommended airow rate for normal aeration of shelled corn, soybeans, and small grainsat 1 Pa (0.5 in 2O) is 5 m3h/H1m/H1of grain (0.1 cfm bu/H (. Aeration of damp grain at 5 Pa (2 in 2O) requires higher ow rates of the order of 5 m3h/H1m/H1of grain (1 cfm bu/H (. It is important that the aeration fan should not be run when the relative humidity of the ambient air is too high. For example, during fall and winter, the operator shouldselect days when the average relative humidity is less than or equal to 7% (, and theair temperature is more than /H1.1C (3F). Furthermore, bins of 4 3(1 bu) or less generally do not require aeration if the grain is loaded dry. 2.2 Natural Air Drying Natural air drying requires higher airow rates than those used for aeration, but is con- ducted in the same type of setup, as just described. Airow rates are typically 1m 3h/H1m/H1(3 cfm/bu) and 2 m3h/H1m/H1(5 cfm/bu) for bed depths of 1.2 1.8 (4 ft), respectively (. These gures apply to small grains, peas, and beans, andshelled and ear corn (. 2.3 In-Storage Drying with Supplemental Heat Drying can be accomplished in the storage bin by vent

upward orsucked down through the grain is largely matter of choice. Upward ventilation is morecommonly used, although there are advantages and disadvantages to each of these meth- ods. An important advantage of using upward ventilation is that it allows storage tempera- tures to be measured easily because the warmest air is always at the top of the pile. Therecommended airow rate for normal aeration of shelled corn, soybeans, and small grainsat 1 Pa (0.5 in 2O) is 5 m3h/H1m/H1of grain (0.1 cfm bu/H (. Aeration of damp grain at 5 Pa (2 in 2O) requires higher ow rates of the order of 5 m3h/H1m/H1of grain (1 cfm bu/H (. It is important that the aeration fan should not be run when the relative humidity of the ambient air is too high. For example, during fall and winter, the operator shouldselect days when the average relative humidity is less than or equal to 7% (, and theair temperature is more than /H1.1C (3F). Furthermore, bins of 4 3(1 bu) or less generally do not require aeration if the grain is loaded dry. 2.2 Natural Air Drying Natural air drying requires higher airow rates than those used for aeration, but is con- ducted in the same type of setup, as just described. Airow rates are typically 1m 3h/H1m/H1(3 cfm/bu) and 2 m3h/H1m/H1(5 cfm/bu) for bed depths of 1.2 1.8 (4 ft), respectively (. These gures apply to small grains, peas, and beans, andshelled and ear corn (. 2.3 In-Storage Drying with Supplemental Heat Drying can be accomplished in the storage bin by vent| Model Type | Bevel-helical gear Reduction Box B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 38000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Guss Gmbh & Co. Kg |

| Country of Manufacture | Slovenia |

| Data Sheet & Drawings | Bevel-helical gear Reduction Box B2 elative to the low speed shaft LSS of a gear unit B2-HH-10-A |