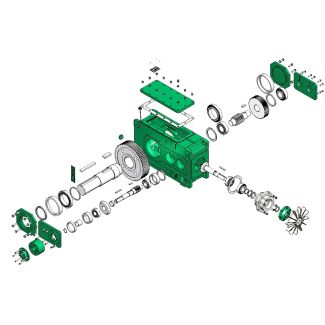

Bevel-helical gear reducer B2 C H C Type Size NDIN D D G l kg Hollow sh B2-FH-17B

In stock

SKU

B2-FH-17B

$210,000.00

Flender/Flender Gear Units/Bevel-helical gear reducer B2

ns should be dried to proper moisture content and stored for days so that the hulls separate from the cotyledons easily after cracking (. drying air relative humiditybelow 4% results in cracks in the soybean seed coat and separation of

easily after cracking (. drying air relative humiditybelow 4% results in cracks in the soybean seed coat and separation of  the seed coat from the cotyledons. In the conventional system of soybean dehulling, beans are dried to about 1% moisture

the seed coat from the cotyledons. In the conventional system of soybean dehulling, beans are dried to about 1% moisture  content and cooled and tempered for moisture uniformity before dehulling. Inuidized-beds, beans (up to 1% moisture content) are heated rapidly

content and cooled and tempered for moisture uniformity before dehulling. Inuidized-beds, beans (up to 1% moisture content) are heated rapidly  to dry enough forcracking without needing to cool the beans. Dehulling and Splitting Pulses 4 Heated beans are cracked to halves in single pair of cracking mills and then fed to an impacter to knock the hull loose from the bean. At higher temperature, short timeand uniform heating result in easier dehulling. 3.2.4.1 Sun Drying Normally, sun drying is practiced in drying yards. However, enterprises with limited space use roof tops for drying. Grains are spread in thin layer (3 cm) and turned frequentlywith rake for even drying. Some dal millers prefer thick layers (up to 1 cm) of grainsin the drying yard for reasons of quality improvement. The drying period for grains variesfrom 1 to 5 days depending on weather conditions, thickness of layer, and pulse crop.The size of the drying yard depends on the capacity of the mill, availability of land, and recommendation of the manufacturer. Most of the dal millers employ sun-drying in open drying yards: 0 2/kg of pulse is sometimes used as rule of thumb. Some millers avoid drying or reduce drying time and mill the pulses after tempering for 8 . This results in heavy breakage during milling. Some of the dal mills areequipped with dryers, but these are preferably used in the rainy season or in situations ofunfavorable weather conditions. Some mechanical dal dryers have been introduced bydifferent rms. Some technical data are reported in Table 6. 3.2.4.2 Losses in Conditioning Some pulses such as green gram and pigeon pea have t

to dry enough forcracking without needing to cool the beans. Dehulling and Splitting Pulses 4 Heated beans are cracked to halves in single pair of cracking mills and then fed to an impacter to knock the hull loose from the bean. At higher temperature, short timeand uniform heating result in easier dehulling. 3.2.4.1 Sun Drying Normally, sun drying is practiced in drying yards. However, enterprises with limited space use roof tops for drying. Grains are spread in thin layer (3 cm) and turned frequentlywith rake for even drying. Some dal millers prefer thick layers (up to 1 cm) of grainsin the drying yard for reasons of quality improvement. The drying period for grains variesfrom 1 to 5 days depending on weather conditions, thickness of layer, and pulse crop.The size of the drying yard depends on the capacity of the mill, availability of land, and recommendation of the manufacturer. Most of the dal millers employ sun-drying in open drying yards: 0 2/kg of pulse is sometimes used as rule of thumb. Some millers avoid drying or reduce drying time and mill the pulses after tempering for 8 . This results in heavy breakage during milling. Some of the dal mills areequipped with dryers, but these are preferably used in the rainy season or in situations ofunfavorable weather conditions. Some mechanical dal dryers have been introduced bydifferent rms. Some technical data are reported in Table 6. 3.2.4.2 Losses in Conditioning Some pulses such as green gram and pigeon pea have t| Model Type | Bevel-helical gear reducer B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 5.6…18 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 195000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Corporation |

| Country of Manufacture | China |

| Data Sheet & Drawings | Bevel-helical gear reducer B2 C H C Type Size NDIN D D G l kg Hollow sh B2-FH-17B |