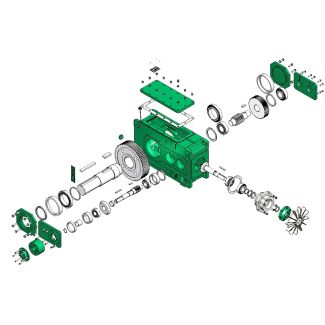

Bevel-helical speed reducer B2 N H H D N H H D Type Size c d D k ns t B2FH-17-C

In stock

SKU

B2FH-17-C

$210,000.00

Flender/Flender Gear Units/Bevel-helical speed reducer B2

ns through both shafts and couplings. The gearbox base is fitted on skid that can be excited by foundation vibrations. Gearbox performance is also influenced by the qualityof the oil, .., oil flow, correct input of oil pressure andtemperature, constant

Gearbox performance is also influenced by the qualityof the oil, .., oil flow, correct input of oil pressure andtemperature, constant  oil physical properties, no contamination bywater or metallic particles, sufficient aeration time in oil tank, etc.Sometimes, transient changes in the

oil physical properties, no contamination bywater or metallic particles, sufficient aeration time in oil tank, etc.Sometimes, transient changes in the  process conditions caninfluence gearbox behavior, for example, during startup withtorsional torque, or in case of false electrical coupling on the

process conditions caninfluence gearbox behavior, for example, during startup withtorsional torque, or in case of false electrical coupling on the  generator, compressor surge, entry of water in the compressor, or when casing thermal expansion produces misalignment betweenmachines. For reasons such as these, troubleshooting on gearboxes is often difficult. well-known methodology is to go step-by-step fromquality claim to measurements and research of correlationsbetween parameters, from measurement to diagnostics, and at thevery least, from correct diagnosis to improvement. In correlation research between the parameters, some effects of secondary cause can hide the primary cause. To avoid problems, investigation on gearboxes requires good knowledge of gear andsleeve bearing operation, as well as skill in the use of modernmeasurement tools. The first step in diagnosis is the analysis of pertinent measurements, inside and outside the gearbox. Sometimes, service companies carry out this first step, but theyoften record information that is not sufficient for correct diagnosis of the problem. Gear manufacturers, with experience in the turbo market, are not only able to collect the data required for problemdiagnosis, but also have the experience necessary to decide themost effective course of action. The gearbox manufacturer is not only the supplier of one component, he is specialist working in partnership with the OEM, engineering companies, and end-users. INSTRUMENTATION ON GEARBOXES Gearbox protection and maintenance are mainly based on vibration measurement (shafts an

generator, compressor surge, entry of water in the compressor, or when casing thermal expansion produces misalignment betweenmachines. For reasons such as these, troubleshooting on gearboxes is often difficult. well-known methodology is to go step-by-step fromquality claim to measurements and research of correlationsbetween parameters, from measurement to diagnostics, and at thevery least, from correct diagnosis to improvement. In correlation research between the parameters, some effects of secondary cause can hide the primary cause. To avoid problems, investigation on gearboxes requires good knowledge of gear andsleeve bearing operation, as well as skill in the use of modernmeasurement tools. The first step in diagnosis is the analysis of pertinent measurements, inside and outside the gearbox. Sometimes, service companies carry out this first step, but theyoften record information that is not sufficient for correct diagnosis of the problem. Gear manufacturers, with experience in the turbo market, are not only able to collect the data required for problemdiagnosis, but also have the experience necessary to decide themost effective course of action. The gearbox manufacturer is not only the supplier of one component, he is specialist working in partnership with the OEM, engineering companies, and end-users. INSTRUMENTATION ON GEARBOXES Gearbox protection and maintenance are mainly based on vibration measurement (shafts an| Model Type | Bevel-helical speed reducer B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 9800.000000 |

| Ratio Range | 1 : 5.6…18 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 195000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | F. H. Transmissiones S.A |

| Country of Manufacture | Chile |

| Data Sheet & Drawings | Bevel-helical speed reducer B2 N H H D N H H D Type Size c d D k ns t B2FH-17-C |