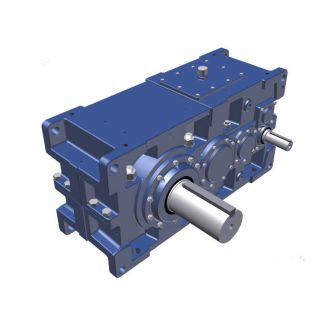

H4SV-17-C company and us Flender GmbH Flender stands for c Helical speed reducer H4

In stock

SKU

H4SV-17-C

$49,178.57

Flender/Flender Gear Units/Helical speed reducer H4

fety problems limit the application of other surface preparation procedure and hence dones not appear in the specifications of paint systems. Hand tool cleaning normally consists of the following: . Hand descaling and/ or hammering . Hand scraping . Hand

systems. Hand tool cleaning normally consists of the following: . Hand descaling and/ or hammering . Hand scraping . Hand  wire brushing Rust, mill scale spatters, old coating and other foreign matter, shall be removed by hammering, scrapping tools, emery

wire brushing Rust, mill scale spatters, old coating and other foreign matter, shall be removed by hammering, scrapping tools, emery  paper cleaning, wire brushing or combination of the above methods. On completion of cleaning, oose materials shall be removed from

paper cleaning, wire brushing or combination of the above methods. On completion of cleaning, oose materials shall be removed from  the surface by clean rags and the surface shall be brushed, swept, deducted and blown off with compressed air/ steam to remove all loose matter. Finally the surface may be washed with water effective cleaning. 5.3 Non compatible shop coat primer The compatibility of finishing coat should be confirmed from the paint manufacturer. In the event of use of primer such as zinc rich epoxy, inorganic zinc silicate etc. as shop coat the pant system shall depend on condition of shop coat, if shop coat is in satisfactory condition showing no major defects, the shop 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 8 of 5 TITLE MEC//0/2/0 REVISION : 0 SHOP & FIELD PAINTING EDITION : 1 coat shall not be removed. The touch up primer and finishing coat() shall be identified for application by Engineer-in-Charge. 5.4 Shop coated (coated with primer & finishing coat) equipment should not be repainted unless paint is damaged. 5.5 Shop primed equipment and surface will only be spot cleaned in damaged areas by means of power tool brush cleaning and then spot primed before applying one coat of filed primer unless otherwise specified. If shop primer is not compatible with field primer then shop coated primer should be completely removed before applications of selected paints system for particular environment. 5.6 For packaged units/ equipment, shop primer should be as per th

the surface by clean rags and the surface shall be brushed, swept, deducted and blown off with compressed air/ steam to remove all loose matter. Finally the surface may be washed with water effective cleaning. 5.3 Non compatible shop coat primer The compatibility of finishing coat should be confirmed from the paint manufacturer. In the event of use of primer such as zinc rich epoxy, inorganic zinc silicate etc. as shop coat the pant system shall depend on condition of shop coat, if shop coat is in satisfactory condition showing no major defects, the shop 1 of 1 STANDARD TECHNICAL SPECIFICATION MECON LIMITED REGD. OFF: RANCHI 8 OIL & GAS SBU, DELHI DOCUMENT NO. Page 8 of 5 TITLE MEC//0/2/0 REVISION : 0 SHOP & FIELD PAINTING EDITION : 1 coat shall not be removed. The touch up primer and finishing coat() shall be identified for application by Engineer-in-Charge. 5.4 Shop coated (coated with primer & finishing coat) equipment should not be repainted unless paint is damaged. 5.5 Shop primed equipment and surface will only be spot cleaned in damaged areas by means of power tool brush cleaning and then spot primed before applying one coat of filed primer unless otherwise specified. If shop primer is not compatible with field primer then shop coated primer should be completely removed before applications of selected paints system for particular environment. 5.6 For packaged units/ equipment, shop primer should be as per th| Model Type | Helical speed reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | Slovakia |

| Data Sheet & Drawings | H4SV-17-C company and us Flender GmbH Flender stands for c Helical speed reducer H4 |