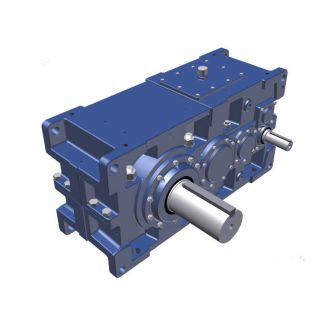

H4-SV-17-D omprehensive knowledge of all aspects of mechan Helical speed reduction gearbox H4

In stock

SKU

H4-SV-17-D

$49,178.57

Flender/Flender Gear Units/Helical speed reduction gearbox H4

fficiency maximization and process stability.Cement | MineralsFocus 2/2 Holcim staff underwent two months of intensive training in PCS7Standardization and uniformity In line with global initiative aimed at reducing the complexity and variation of automation systems installed in its worldwide facilities,

In line with global initiative aimed at reducing the complexity and variation of automation systems installed in its worldwide facilities,  Cajanders teams led Holcim Philippines in the imple-mentation of carefully considered and extremely structured replacement strategy, which was anchored on

Cajanders teams led Holcim Philippines in the imple-mentation of carefully considered and extremely structured replacement strategy, which was anchored on  standardization and uniformity. Holcims primary objectives for the upgrade program are operation sustain- ability, overall equipment efficiency maximization and process

standardization and uniformity. Holcims primary objectives for the upgrade program are operation sustain- ability, overall equipment efficiency maximization and process  stability. Their long-term goal is to streamline manufacturing technologies across the company by standardizing the plant equipment and engineering processes in its global operations. Ideally, whichever automation brand is implemented in particular region, it would have the same architecture, wir - ing concept, engineering and documen-tation approach. So whatever country you are in, their plants electrical, instru-mentation and automation systems should all look essentially the same. Reliable partner In their search for suitable automa-tion partner, the number one criteria was local presence. It was important to them that their automation supplier had the necessary expertise and could guarantee centralized and dedicated support over the long term. Cajander emphasizes: Compared to some years ago, the field of automa-tion has strongly evolved. myriad of factors such as advancements in tech- nology and changing market needs have led to its growing complexity. As such, you need to develop exper - tise in various fields including IT, elec-tricals, instrumentation, and process and control systems. This means you also need to cultivate much closer relationship with your supplier.Of course, price and other commercial aspects are important, but with 2/7, capital-intensive operation such as ours, ensuring uptime of the plant

stability. Their long-term goal is to streamline manufacturing technologies across the company by standardizing the plant equipment and engineering processes in its global operations. Ideally, whichever automation brand is implemented in particular region, it would have the same architecture, wir - ing concept, engineering and documen-tation approach. So whatever country you are in, their plants electrical, instru-mentation and automation systems should all look essentially the same. Reliable partner In their search for suitable automa-tion partner, the number one criteria was local presence. It was important to them that their automation supplier had the necessary expertise and could guarantee centralized and dedicated support over the long term. Cajander emphasizes: Compared to some years ago, the field of automa-tion has strongly evolved. myriad of factors such as advancements in tech- nology and changing market needs have led to its growing complexity. As such, you need to develop exper - tise in various fields including IT, elec-tricals, instrumentation, and process and control systems. This means you also need to cultivate much closer relationship with your supplier.Of course, price and other commercial aspects are important, but with 2/7, capital-intensive operation such as ours, ensuring uptime of the plant| Model Type | Helical speed reduction gearbox H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2295.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender LTD., KOREA |

| Country of Manufacture | Slovenia |

| Data Sheet & Drawings | H4-SV-17-D omprehensive knowledge of all aspects of mechan Helical speed reduction gearbox H4 |