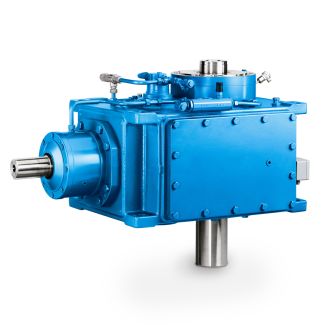

H4KH-17-C nit on the basis of the thermal capacity but a le Helical speed reduction gearboxes H4

In stock

SKU

H4KH-17-C

$74,464.29

Flender/Flender Gear Units/Helical speed reduction gearboxes H4

investment, hoping that profits earned in untapped markets overseas will be reinvested in domestic operations. 1 Other Competitive Factors Taiwan does not have its own standards for gearing. Both the Japanese Industrial Standards (JIS) and the American Gear Manufacturers Association

does not have its own standards for gearing. Both the Japanese Industrial Standards (JIS) and the American Gear Manufacturers Association  (AGMA) gearing standards are commonly used in Taiwan. However, Taiwan' gear producers complain that lack of uniform standards have complicated

(AGMA) gearing standards are commonly used in Taiwan. However, Taiwan' gear producers complain that lack of uniform standards have complicated  communication with customers, as well as made machinery purchases more difficult. 1 Taiwan' gear producers have not been reluctant to

communication with customers, as well as made machinery purchases more difficult. 1 Taiwan' gear producers have not been reluctant to  invest in machinery and equip- ment during the recent period of economic prosperity. Some manufacturers have updated their machinery in the last 5 or 6 years, purchasing computer numerically controlled machines from the United States and West Germany. In 1, Taiwan imports of gear-cutting machine tools totaled $6.4 million. According to Taiwan industry sources, about 5 to 6 percent of Taiwan' gear production machinery is less than 1 years old. 1 Automation is generally limited because of the small size of customers' orders received by the industry. The number of gear grinding machines, which are important in manufactur- ing precision gears, rose from 1 in 1 to 4 in 1. Gear manufacturers have also been purchasing more machinery for automatic worm gear grinding and gear hobbing, as well as CAD/CAM systems, advanced heat treatment machinery, and precision testing and measurement equipment. Production is fairly capital intensive, and productivity, backed by strong work ethic, is high. Because of their investment in modern Unpublished data from the .. Bureau of Labor Statistics, August 1. USITC staff interview with industry official stationed in the Far East, October 1. ' American Institute in Taiwan AiTram, December 1, Taipei, Message Reference No. 0. " "Taiwan Firms Head Overseas as Costs Increase Home," The Asian Wall Street Journal Weekly, Aug. 1, 1, . . 1 American Institute in Taiwan

invest in machinery and equip- ment during the recent period of economic prosperity. Some manufacturers have updated their machinery in the last 5 or 6 years, purchasing computer numerically controlled machines from the United States and West Germany. In 1, Taiwan imports of gear-cutting machine tools totaled $6.4 million. According to Taiwan industry sources, about 5 to 6 percent of Taiwan' gear production machinery is less than 1 years old. 1 Automation is generally limited because of the small size of customers' orders received by the industry. The number of gear grinding machines, which are important in manufactur- ing precision gears, rose from 1 in 1 to 4 in 1. Gear manufacturers have also been purchasing more machinery for automatic worm gear grinding and gear hobbing, as well as CAD/CAM systems, advanced heat treatment machinery, and precision testing and measurement equipment. Production is fairly capital intensive, and productivity, backed by strong work ethic, is high. Because of their investment in modern Unpublished data from the .. Bureau of Labor Statistics, August 1. USITC staff interview with industry official stationed in the Far East, October 1. ' American Institute in Taiwan AiTram, December 1, Taipei, Message Reference No. 0. " "Taiwan Firms Head Overseas as Costs Increase Home," The Asian Wall Street Journal Weekly, Aug. 1, 1, . . 1 American Institute in Taiwan| Model Type | Helical speed reduction gearboxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 3475.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Himmel RSA |

| Country of Manufacture | Nauru |

| Data Sheet & Drawings | H4KH-17-C nit on the basis of the thermal capacity but a le Helical speed reduction gearboxes H4 |