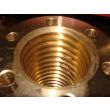

H4HV-11-C delivery kit as far as possible Upon request th Helical speed reducer H4

In stock

SKU

H4HV-11-C

$11,571.43

Flender/Flender Gear Units/Helical speed reducer H4

ibed according to the standard row R2. Since this row is very dense, most manufacturers produce reducers with axis heig ht in standard row R1 (these numbers belong to the standard row R. But soon they increased axis heights in

ht in standard row R1 (these numbers belong to the standard row R. But soon they increased axis heights in  order to increase gear ratio, and now reducers are produced with axis height in standard row R2/2. In the area

order to increase gear ratio, and now reducers are produced with axis height in standard row R2/2. In the area  of the most used gearbox size , some manufacturers produce so -called intermediate sizes ith the axis heights in row

of the most used gearbox size , some manufacturers produce so -called intermediate sizes ith the axis heights in row  R2 [6,7]. In recent time, manufacturers of gear reducers try to achieve the same axis heights in order to ensure greater exchangeability of their gear units. This is specially important for smaller manufacturers, so they can offer their products instead of those of large manufacturers. This additionally means that they must have the same mounting dimensions, .. dimensions of the holes for base screws on the feet or lange and their position, etc. Axis heights of single -stage gear reducers are presented in Table 1 [2]. Based on the axis heights presented in this table, it can be concluded that all manufacturers of single -stage gear reducers cover the interval of axis eight from 6 mm till 1 mm. Some manufacturers also offer smaller or larger heights. As it can be seen no manufacturer fully respect the row R1 or R2/2, but they introduce additional heights, so-called intermediate sizes. For example, axis heights of 9, 1 and 1 mm are often requested, so the large manufacturers produce gear units with this axis height in the row R2. Single -stage reducers with the minimum axis height of 5 mm are only manufactured by Lenze and Bonfiglioli. SEW produces single -stage gearboxes up to the height of 1 mm and Siemens -Flender and Leroy Somer up to 1 mm. Table 1. Axis heights of single -stage gear reducers for different manufacturers [2]. No. Gear reducer manufacturer Numbers in standard row R2 5 5 6 7 8 9 1 1 1 1 1 1. SEW 2. Siemens -Flender

R2 [6,7]. In recent time, manufacturers of gear reducers try to achieve the same axis heights in order to ensure greater exchangeability of their gear units. This is specially important for smaller manufacturers, so they can offer their products instead of those of large manufacturers. This additionally means that they must have the same mounting dimensions, .. dimensions of the holes for base screws on the feet or lange and their position, etc. Axis heights of single -stage gear reducers are presented in Table 1 [2]. Based on the axis heights presented in this table, it can be concluded that all manufacturers of single -stage gear reducers cover the interval of axis eight from 6 mm till 1 mm. Some manufacturers also offer smaller or larger heights. As it can be seen no manufacturer fully respect the row R1 or R2/2, but they introduce additional heights, so-called intermediate sizes. For example, axis heights of 9, 1 and 1 mm are often requested, so the large manufacturers produce gear units with this axis height in the row R2. Single -stage reducers with the minimum axis height of 5 mm are only manufactured by Lenze and Bonfiglioli. SEW produces single -stage gearboxes up to the height of 1 mm and Siemens -Flender and Leroy Somer up to 1 mm. Table 1. Axis heights of single -stage gear reducers for different manufacturers [2]. No. Gear reducer manufacturer Numbers in standard row R2 5 5 6 7 8 9 1 1 1 1 1 1. SEW 2. Siemens -Flender| Model Type | Helical speed reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 540.000000 |

| Ratio Range | 1 : 100…355 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 61600 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Macneill Gears Ltd. |

| Country of Manufacture | Tajikistan |

| Data Sheet & Drawings | H4HV-11-C delivery kit as far as possible Upon request th Helical speed reducer H4 |