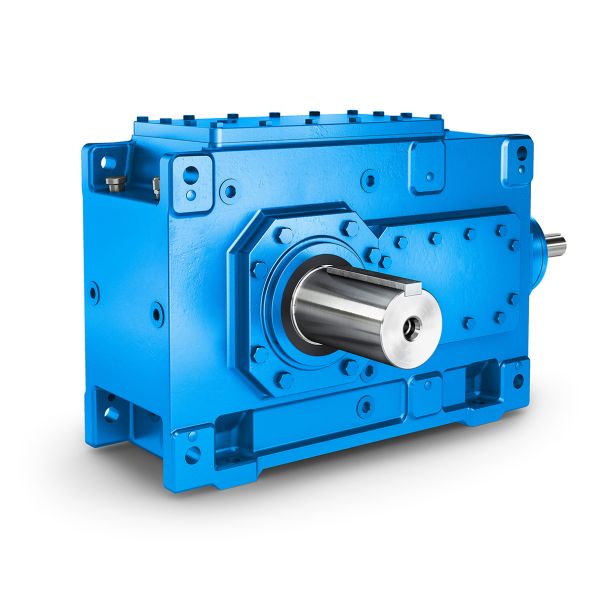

H4-VV24A HE PERFECT GEAR UNIT We provide elastic highly el Helical gear reducers H4

In stock

SKU

H4-VV24A

$173,571.43

Flender/Flender Gear Units/Helical gear reducers H4

General information on maintenance Note: All maintenance and repair work should be carried out with due care and only by thoroughly trained personnel. The notes in Section 2. Safety notes should be observed. The periods listed in Table 1.1 are

thoroughly trained personnel. The notes in Section 2. Safety notes should be observed. The periods listed in Table 1.1 are  largely dependent on the conditions of use of the gear unit. For this reason, it is only possible to give

largely dependent on the conditions of use of the gear unit. For this reason, it is only possible to give  average periodswhich refer to - daily operating time of 2 - duty factor of ED 1 %- input drive speed

average periodswhich refer to - daily operating time of 2 - duty factor of ED 1 %- input drive speed  of 1 min - max. oil temperature of 9 (with mineral oils, CLP) 1C (with synth. oils, PGLP) Note: Under different operating conditions, the periods should be adjusted accordingly. Measures Causes Remedy Observe/check gear unit noise for changesfrom time to time, more often during operation if possible- Observe/check oil temperaturefrom time to time, more often during operation if possible- Oil level check monthly see 7.1.1 Check gear unit for leakage monthly - Initial oil change after startupafter approx. 1 operating hours, at the latest after 3 yearssee 1.2.1 Subsequent oil changesevery 3 years or 1 operating hours see 1.2.1 Relubrication of anti-frictionbearings jannualy or every 5 operating hours see 1.2.2 Clean ventilator filter every 3 months see 1.2.3 Clean driveaccording to the degree of contaminationsee 1.2.4 Check all fixing screws fortightnessat least once year see 1.2.5 Carry out complete inspection ofgear unitat least once year see 1.2.6 Table 1.1: Maintenance and repairs With synthetic oils (PGLP), the times can be doubled. The specified grease service lives apply with max. ambient temperature of 4 . The grease service life must be decreased by factor of 0,7 for every 1 rise in temperature (max. 2 C = factor 0,. With an ambient temperature of 2 C double the grease service life can be expected .Attention! BA G2 EN 0.0 3 / 4.2 Description of maintenance and repairs 1.2.1 Perform oil change or oil flushing Different types of oil must not be mixed. Note: Types of oil: - mine

of 1 min - max. oil temperature of 9 (with mineral oils, CLP) 1C (with synth. oils, PGLP) Note: Under different operating conditions, the periods should be adjusted accordingly. Measures Causes Remedy Observe/check gear unit noise for changesfrom time to time, more often during operation if possible- Observe/check oil temperaturefrom time to time, more often during operation if possible- Oil level check monthly see 7.1.1 Check gear unit for leakage monthly - Initial oil change after startupafter approx. 1 operating hours, at the latest after 3 yearssee 1.2.1 Subsequent oil changesevery 3 years or 1 operating hours see 1.2.1 Relubrication of anti-frictionbearings jannualy or every 5 operating hours see 1.2.2 Clean ventilator filter every 3 months see 1.2.3 Clean driveaccording to the degree of contaminationsee 1.2.4 Check all fixing screws fortightnessat least once year see 1.2.5 Carry out complete inspection ofgear unitat least once year see 1.2.6 Table 1.1: Maintenance and repairs With synthetic oils (PGLP), the times can be doubled. The specified grease service lives apply with max. ambient temperature of 4 . The grease service life must be decreased by factor of 0,7 for every 1 rise in temperature (max. 2 C = factor 0,. With an ambient temperature of 2 C double the grease service life can be expected .Attention! BA G2 EN 0.0 3 / 4.2 Description of maintenance and repairs 1.2.1 Perform oil change or oil flushing Different types of oil must not be mixed. Note: Types of oil: - mine| Model Type | Helical gear reducers H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 8100.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 725000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens Industriegetriebe GmbH, Penig |

| Country of Manufacture | China |

| Data Sheet & Drawings | H4-VV24A HE PERFECT GEAR UNIT We provide elastic highly el Helical gear reducers H4 |