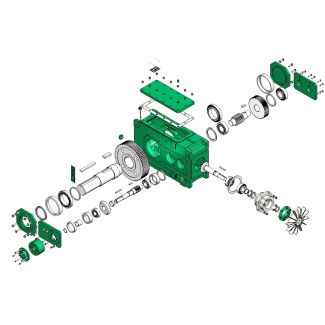

H4-VV-18-D of which demands are made on the coupling Low o Helical gear reducer H4

In stock

SKU

H4-VV-18-D

$56,250.00

Flender/Flender Gear Units/Helical gear reducer H4

gear unit needs time to stabilize. If after 2 seconds no oil pressure has built up, the time can be extended slightly with the approval of the manufacturer. 7.3.3 Breather Check that no water condensation can get into the gear

extended slightly with the approval of the manufacturer. 7.3.3 Breather Check that no water condensation can get into the gear  unit. For this the ventilation system must be laid by extension by the customer. 7.3.4 Gear unit with backstop Before

unit. For this the ventilation system must be laid by extension by the customer. 7.3.4 Gear unit with backstop Before  startup, check whether the backstop can be turned manually in the freewheeling direction without exerting undue force. Observe the directionofrotation

startup, check whether the backstop can be turned manually in the freewheeling direction without exerting undue force. Observe the directionofrotation  arrows on the housing. To check the direction of motor rotation, undo the coupling connection, if necessary. To avoid damaging the backstop or the gear unit, the motor must not be run in the stop direction of the gear unit.Observe the notice fixed to the gear unit. 7.3.5 Pressure lubrication by flange oder motor pump The oilsupply elements are permanently attached to the gear unit and consist of flange or motor pump, coarse filter, pressuremonitoring device and the required pipework. The coarse filter may in particularin the case of gear units from size 1 upwards be replaced with double change-over filter. With gear units with added oilsupply system, the pressure monitor must always be connected before starting up the unit. Note: The operation and maintenance of the pump, pressure monitor and coarse filter are described in instructions included (where applicable) with the products. For technical data, refer to the orderspecific list of equipment and the dimensioned drawing. If heating element is fitted, the conditions for starting up the heating system must be followed. The motor pump must be started 5 minutes before starting up the gear unit.Caution! Caution! Caution! Caution! 2 / 3BA 5 EN 1.0.3.6 Checks before startup The following visual checks must be conducted before startup: Oil level Freedom of the rotating parts from contact 7.3.7 Checks during startup The following visual checks must be conducted during operation:Effectiveness of the shaft seals Freedom of the ro

arrows on the housing. To check the direction of motor rotation, undo the coupling connection, if necessary. To avoid damaging the backstop or the gear unit, the motor must not be run in the stop direction of the gear unit.Observe the notice fixed to the gear unit. 7.3.5 Pressure lubrication by flange oder motor pump The oilsupply elements are permanently attached to the gear unit and consist of flange or motor pump, coarse filter, pressuremonitoring device and the required pipework. The coarse filter may in particularin the case of gear units from size 1 upwards be replaced with double change-over filter. With gear units with added oilsupply system, the pressure monitor must always be connected before starting up the unit. Note: The operation and maintenance of the pump, pressure monitor and coarse filter are described in instructions included (where applicable) with the products. For technical data, refer to the orderspecific list of equipment and the dimensioned drawing. If heating element is fitted, the conditions for starting up the heating system must be followed. The motor pump must be started 5 minutes before starting up the gear unit.Caution! Caution! Caution! Caution! 2 / 3BA 5 EN 1.0.3.6 Checks before startup The following visual checks must be conducted before startup: Oil level Freedom of the rotating parts from contact 7.3.7 Checks during startup The following visual checks must be conducted during operation:Effectiveness of the shaft seals Freedom of the ro| Model Type | Helical gear reducer H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 2625.000000 |

| Ratio Range | 1 : 112…400 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 240000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Limited. |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | H4-VV-18-D of which demands are made on the coupling Low o Helical gear reducer H4 |