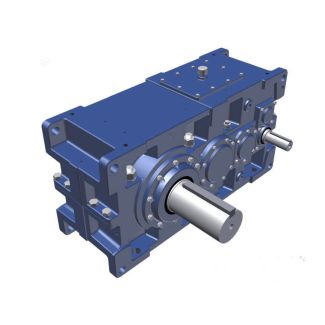

H4-SH-12-D flender linkedin Helical gear boxes H4

In stock

SKU

H4-SH-12-D

$21,857.14

Flender/Flender Gear Units/Helical gear boxes H4

evenly across the full 2 Sarkar () () () Fig. 2 () modern purier; () air being drawn up through the sieves; () underside of purier sieve showing brush. (Courtesy of Bu hler, Inc.) width of the sieve layer. The

the sieves; () underside of purier sieve showing brush. (Courtesy of Bu hler, Inc.) width of the sieve layer. The  uid bed of material begins to stratify as result of the combination of controlled air that is drawn up through

uid bed of material begins to stratify as result of the combination of controlled air that is drawn up through  the sieves and oscillation of the sieve layers. Stratication of material according to density causes the lowest-density mate-rial to rise

the sieves and oscillation of the sieve layers. Stratication of material according to density causes the lowest-density mate-rial to rise  to the top and where it is removed by air under suction. The lighter brannymaterial and germ particles with endosperm attached is carried all the way to the end ofthe sieve layers and exit the machine from spouts at the tail end. Pure granular endospermparticles being dense fall through the sieve layers. All the material dropping through thesieve layers, beginning from head end of the machine to the tail end, can be collected into one shaking channel at the bottom. However, near the tail end of the machine, the material starts to thin out; consequently, impure material of bran and germ with someendosperm attached may begin to drop through. When this becomes evident, while exam-ining the material under the purier, aps over the channels can be deected to collectthe impure material in the second channel. Grain-Milling Operations 2 3.3.5 Flour-Milling Equipment Layout The most common conguration of milling equipment layout involves placement of roller- mills one oor above the ground oor (Fig. . Material, once ground in rollermill, iscarried by pneumatic conveying (see Fig. , to the sifter, which is generally located three oors above the ground level. Puriers and bran nishers or dusters, which are used to remove the last traces of endosperm from the bran, are usually located two oors abovethe ground level. The purpose of having multistory building for our mills is to takefull advantage of the gravity to feed various equipment in sequential operation. If twopieces of equipment are located on oors above each other

to the top and where it is removed by air under suction. The lighter brannymaterial and germ particles with endosperm attached is carried all the way to the end ofthe sieve layers and exit the machine from spouts at the tail end. Pure granular endospermparticles being dense fall through the sieve layers. All the material dropping through thesieve layers, beginning from head end of the machine to the tail end, can be collected into one shaking channel at the bottom. However, near the tail end of the machine, the material starts to thin out; consequently, impure material of bran and germ with someendosperm attached may begin to drop through. When this becomes evident, while exam-ining the material under the purier, aps over the channels can be deected to collectthe impure material in the second channel. Grain-Milling Operations 2 3.3.5 Flour-Milling Equipment Layout The most common conguration of milling equipment layout involves placement of roller- mills one oor above the ground oor (Fig. . Material, once ground in rollermill, iscarried by pneumatic conveying (see Fig. , to the sifter, which is generally located three oors above the ground level. Puriers and bran nishers or dusters, which are used to remove the last traces of endosperm from the bran, are usually located two oors abovethe ground level. The purpose of having multistory building for our mills is to takefull advantage of the gravity to feed various equipment in sequential operation. If twopieces of equipment are located on oors above each other| Model Type | Helical gear boxes H4 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 1020.000000 |

| Ratio Range | 1 : 125…450 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 78000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Ibérica S.A. |

| Country of Manufacture | Canada |

| Data Sheet & Drawings | H4-SH-12-D flender linkedin Helical gear boxes H4 |